Unveiling the 2025 Tech Trends: How the Best Industrial Packing Machines are Redefining Efficiency

In the rapidly evolving landscape of global manufacturing, the role of the Industrial Packing Machine has become increasingly pivotal in redefining operational efficiency and productivity. A recent report by Statista indicates that the global packaging machinery market is projected to reach approximately $55 billion by 2025, fueled by advancements in automation and smart technology. As manufacturers strive to optimize their processes and reduce waste, investing in high-performance packing solutions is no longer optional but a necessity. The best industrial packing machines are not just enhancing throughput; they are also integrating sophisticated features such as IoT connectivity and AI-driven analytics, which enable real-time monitoring and continuous improvement.

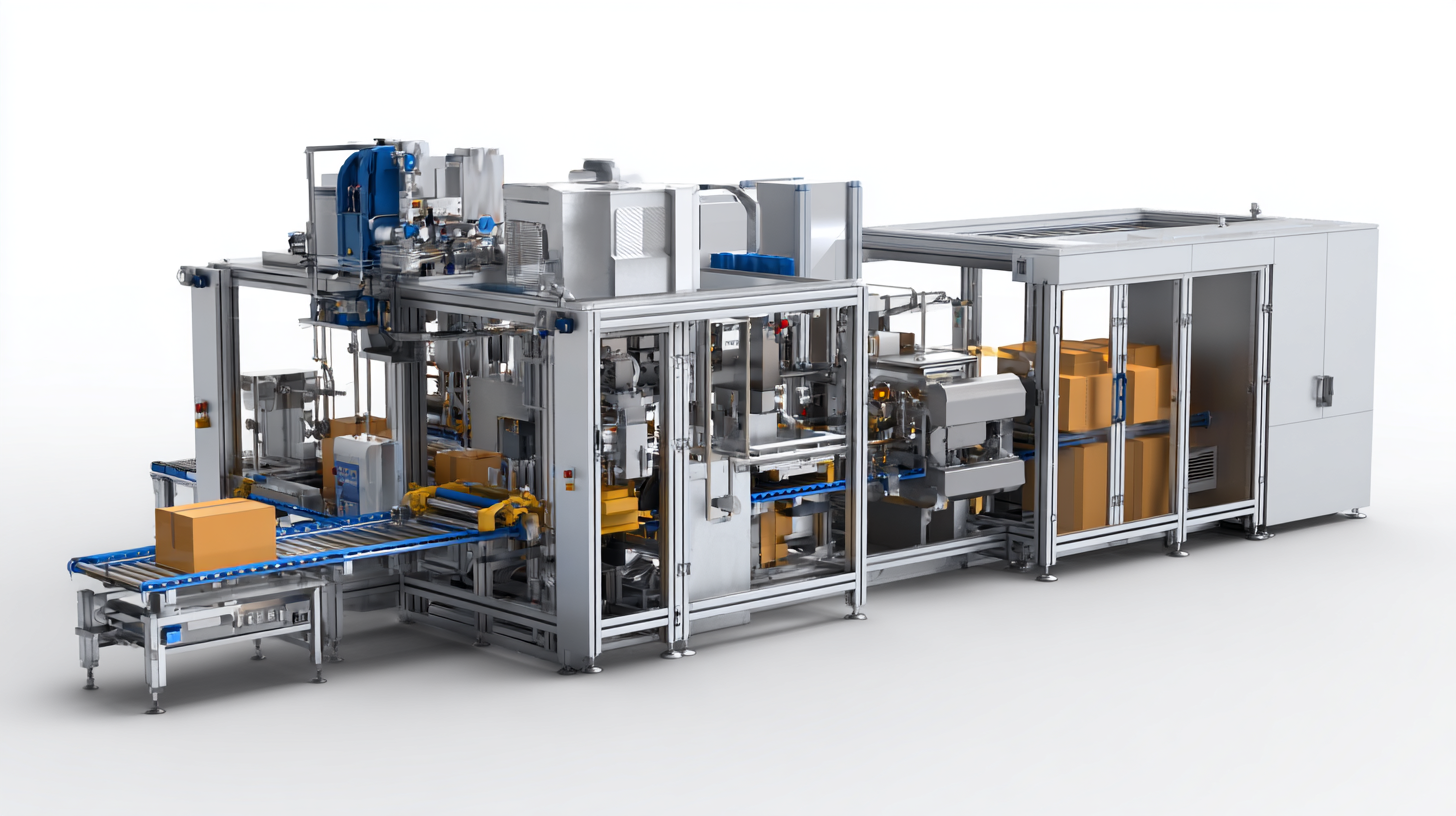

This blog will explore the 2025 tech trends that showcase how these innovations in industrial packing machines are setting new benchmarks for efficiency, especially among leading manufacturers that are ranked at the top of the global export charts.

The Rise of Automation: Key Statistics on Industrial Packing Efficiency in 2025

The landscape of industrial packing is undergoing a remarkable transformation, driven predominantly by the rise of automation. By 2025, companies are expected to realize a staggering 30% increase in packing efficiency through the implementation of automated systems. This shift not only streamlines operations but also significantly reduces labor costs, allowing businesses to allocate resources more effectively. Advanced sensors and AI-driven technologies are paving the way for packing machines that can adapt to varying product sizes and packaging types, ensuring optimal performance without compromising quality.

Recent statistics indicate that over 70% of industrial packing operations will prioritize automated solutions by 2025. This trend is not just about speed; it's also about precision and consistency. Automation minimizes human error, leading to higher product integrity and reduced waste. Companies leveraging these cutting-edge packing machines are expected to boost their profit margins by up to 25%. As the industry embraces this change, the future looks promising for those who invest in technology that enhances efficiency and responsiveness in their packing processes.

Innovative Materials in Packing: Analyzing Trends and Their Impact on Sustainability

The landscape of industrial packing is undergoing a remarkable transformation, driven by innovative materials that prioritize sustainability without compromising efficiency. As companies look to enhance their operational capabilities, the adoption of eco-friendly packing materials is becoming a major trend. Biodegradable plastics, recycled materials, and plant-based alternatives are gaining traction, reflecting a significant shift toward reducing environmental footprints. These advancements not only meet regulatory demands but also resonate with environmentally conscious consumers who favor brands committed to sustainable practices.

Moreover, the integration of smart technologies with these innovative materials is redefining the packing process. Automated systems that can adapt to using various environmentally friendly materials result in reduced waste and optimized resource usage. For instance, packaging solutions that feature adjustable formats can minimize overpacking, while real-time analytics help manufacturers make informed decisions on material choices. As businesses embrace these trends, the convergence of efficiency and sustainability is not just a goal; it’s becoming a competitive advantage that shapes the future of the packing industry.

AI-Powered Solutions: How Data Analytics is Shaping Packing Machine Performance

In the fast-evolving world of industrial packing, 2025 is poised to be a transformative year,

with AI-powered solutions leading the charge in redefining efficiency. As data analytics increasingly drives decision-making,

packing machine performance has reached new heights. According to a recent report by Smithers Pira, the integration of

advanced data analytics can enhance operational efficiency by up to 30%, allowing manufacturers to better predict

maintenance needs and optimize workflows.

In the fast-evolving world of industrial packing, 2025 is poised to be a transformative year,

with AI-powered solutions leading the charge in redefining efficiency. As data analytics increasingly drives decision-making,

packing machine performance has reached new heights. According to a recent report by Smithers Pira, the integration of

advanced data analytics can enhance operational efficiency by up to 30%, allowing manufacturers to better predict

maintenance needs and optimize workflows.

Implementing AI technologies within packing machines not only streamlines processes but also provides

real-time insights into performance metrics. This capability allows companies

to adjust settings on the fly, ensuring reduced downtime and increased throughput. A study by McKinsey highlights

that digitizing packaging processes can boost productivity by 20-25%, a significant gain for businesses aiming to

remain competitive in a crowded market.

Tips: To maximize the benefits of AI-driven analytics, ensure that your packing machines

are equipped with the latest sensor technology. Regularly review and analyze performance data to identify areas for improvement.

Additionally, consider investing in employee training to enhance their understanding of how to leverage these advanced tools effectively.

Embracing these strategies can lead to substantial long-term gains in productivity and efficiency.

The Role of IoT: Enhancing Connectivity and Real-Time Monitoring in Packing Operations

The industrial packing sector is witnessing a transformative shift as the Internet of Things (IoT) comes to the forefront of operational efficiency. With the integration of smart sensors and devices, packing machines are no longer standalone units but rather interconnected hubs that facilitate seamless communication across the production line. This connectivity allows for real-time monitoring, enabling operators to track performance metrics, detect anomalies, and make data-driven decisions on the fly. As a result, downtime is minimized, and productivity is significantly enhanced.

Real-time monitoring through IoT not only improves efficiency but also ensures higher quality standards. By continuously collecting data on variables such as temperature, humidity, and pressure during the packing process, manufacturers can maintain optimal conditions and prevent potential issues before they escalate. Furthermore, advanced analytics derived from this data can help companies identify patterns, optimize workflows, and predict maintenance needs. Ultimately, the role of IoT in packing operations is reshaping the landscape, leading to smarter, more efficient, and more reliable industrial practices.

Unveiling the 2025 Tech Trends: How the Best Industrial Packing Machines are Redefining Efficiency

| Machine Type | Efficiency (%) | IoT Integration | Real-Time Monitoring | Annual Maintenance Cost ($) |

|---|---|---|---|---|

| Automatic Carton Sealer | 95 | Yes | Yes | 1200 |

| Horizontal Flow Wrapper | 90 | No | Yes | 900 |

| Robotic Packing Station | 98 | Yes | Yes | 1500 |

| Shrink Wrapping Machine | 85 | No | No | 600 |

| Case Packer | 92 | Yes | Yes | 1100 |

Adapting to Consumer Preferences: Statistics on Customization in Industrial Packing Solutions

In the ever-evolving packaging industry, the drive for customization has become paramount, reflecting the urgent need to align with shifting consumer preferences. According to McKinsey's "State of the Consumer 2025" report, over 70% of consumers prioritize personalized experiences, influencing their purchasing decisions in significant ways. This trend is pushing manufacturers to adopt more versatile industrial packing machines that can accommodate a broader range of product specifications and personalization options, ultimately redefining efficiency in the sector.

Recent insights from the narrative review on consumer acceptance of new food trends highlight that plant-based options remain dominant in alternative protein markets, yet there is intensifying interest in niche products tailored to specific consumer demands. Industries are responding to this call, leveraging advanced technologies like AI to develop packing solutions that not only enhance operational efficiency but also allow for high degrees of customization in response to consumer trends. With these transformations, the packaging landscape is poised to meet the dual demands of speed and personalization, keeping pace with the profound changes in consumer behavior.

2025 Tech Trends in Industrial Packing: Customization Preferences

This chart illustrates the percentage of consumers who prefer customization in industrial packing solutions. The data indicates a growing demand for tailored packaging options over the years, highlighting the importance of adapting to consumer preferences.