Understanding the Advantages of the Best Custom Machine for Global Buyers

In an increasingly competitive global market, manufacturers are seeking innovative solutions to enhance productivity and efficiency.

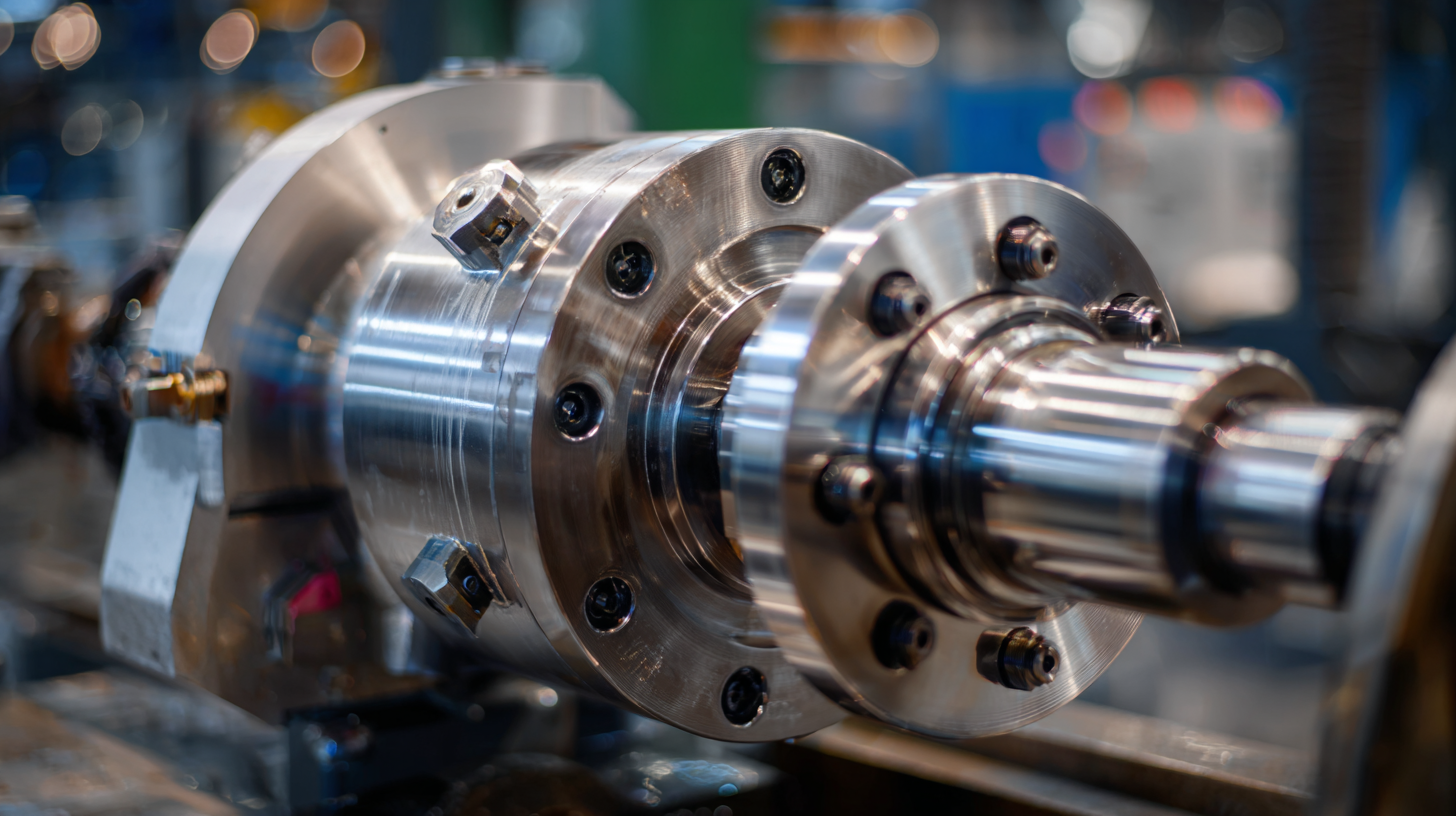

Custom machines have emerged as a vital component in this landscape, catering specifically to the unique needs of various industries.

According to a recent report by MarketsandMarkets, the global custom machine market is expected to grow from $8.5 billion in 2020 to $12.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.9%.

This growth is driven by the demand for specialized manufacturing processes, greater automation, and the ability to optimize production lines.

By investing in the best custom machines, global buyers can not only improve operational efficiency but also tailor their production capabilities to meet specific requirements, resulting in enhanced product quality and reduced lead times.

Understanding the advantages of these custom solutions is crucial for businesses aiming to maintain a competitive edge in their respective markets.

Custom machines have emerged as a vital component in this landscape, catering specifically to the unique needs of various industries.

According to a recent report by MarketsandMarkets, the global custom machine market is expected to grow from $8.5 billion in 2020 to $12.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.9%.

This growth is driven by the demand for specialized manufacturing processes, greater automation, and the ability to optimize production lines.

By investing in the best custom machines, global buyers can not only improve operational efficiency but also tailor their production capabilities to meet specific requirements, resulting in enhanced product quality and reduced lead times.

Understanding the advantages of these custom solutions is crucial for businesses aiming to maintain a competitive edge in their respective markets.

The Rise of Custom Machinery: Why Global Buyers are Embracing Innovation

The rise of custom machinery has become a defining trend in global manufacturing, driven by the need for increased efficiency and adaptability in production processes. According to a report by Grand View Research, the global custom machinery market is projected to grow at a CAGR of 5.2% from 2021 to 2028. This growth reflects manufacturers' shift towards tailored solutions that meet specific operational needs, enabling enhanced productivity and reduced lead times.

Global buyers are increasingly embracing innovation in custom machinery to address the challenges of a fast-evolving market. A survey conducted by McKinsey & Company found that 70% of manufacturers are prioritizing investments in customized equipment to improve operational flexibility. Custom solutions allow businesses to integrate advanced technologies such as IoT and AI, enabling real-time monitoring and predictive maintenance. As competition intensifies, manufacturers recognize that investing in bespoke machinery can significantly differentiate their offerings and drive sustainable growth.

Key Features that Define the Best Custom Machines for Various Industries

When selecting custom machines, global buyers must prioritize specific key features that ensure efficiency and adaptability across various industries. First and foremost, the flexibility of design plays a crucial role. Custom machines that can be tailored to fit different production requirements allow businesses to maintain agility in fast-changing markets. This adaptability also facilitates easy upgrades and modifications, making it easier for companies to scale their operations without substantial investments in new equipment.

Additionally, the integration of advanced technology is vital in the best custom machines. Features such as IoT connectivity and automation not only enhance operational efficiency but also provide real-time data for better decision-making. This technological advancement supports predictive maintenance, reducing downtime and minimizing unexpected failures. Furthermore, user-friendly interfaces and comprehensive support services ensure that operators can easily familiarize themselves with the machine, maximizing productivity and reducing training time. These elements collectively define the ideal custom machine that meets the diverse demands of today’s global market.

Market Trends Impacting Global Demand for Tailored Machinery Solutions

In recent years, the global demand for tailored machinery solutions has surged, driven by several key market trends. The push towards automation and efficiency in various industries has led to increased investments in custom machinery, reflecting a broader movement towards enhancing productivity and reducing operational costs. For instance, the Global Electric Construction Equipment market anticipates significant growth, projected to reach $67.4 billion by 2033 with an impressive CAGR of 18.6%. Such advancements not only align with corporate sustainability goals but also respond to the rising need for innovative solutions in a competitive landscape.

Moreover, the growth of specialized sectors, such as the Global Apheresis Equipment market, is expected to reflect a compound annual growth rate (CAGR) of 12.2% as it approaches $13.2 billion by 2033. This trend highlights a shift in consumer preferences toward customized, efficient, and specialized machinery across various applications. As globalization continues to reshape industries, understanding and adapting to these market dynamics becomes crucial for businesses aiming to thrive in an increasingly tailored economy. Custom machinery solutions not only cater to unique operational needs but also provide a strategic advantage in meeting the evolving demands of global buyers.

Cost-Benefit Analysis: Investing in Custom Equipment vs. Off-the-Shelf Options

When considering whether to invest in custom machinery or stick with off-the-shelf options, a cost-benefit analysis becomes essential.

Custom equipment often comes with a higher upfront cost; however, it can lead to significant long-term savings and operational efficiencies. Tailoring machinery to specific production needs means fewer adjustments and downtime, ensuring that processes run smoothly and meet the unique requirements of a business. This, in turn, can improve product quality and speed up delivery times, enhancing overall customer satisfaction.

On the other hand, off-the-shelf solutions may seem initially more appealing due to lower costs and shorter lead times. However, they may not always align perfectly with a company’s operations, leading to potential inefficiencies and higher operational costs over time. Businesses weighing their options should consider the future scalability, adaptability, and potential for innovation that custom machinery can provide. As the US outdoor power equipment market continues to grow, projected to reach USD 117,626.4 million by 2033, investing in customized solutions could be a strategic move for firms looking to maintain a competitive edge.

Future-Proofing Business Operations: Advantages of Custom Machines by 2025

As businesses prepare for the complexities of 2025, the adoption of custom machines emerges as a strategic advantage for future-proofing operations. The integration of advanced technologies, such as artificial intelligence and advanced automation, ensures that custom machines not only meet current demands but also adapt to future challenges. By leveraging these innovations, companies can enhance efficiency, streamline production processes, and create a more agile response to market shifts.

Moreover, the rapid evolution of logistics and export strategies necessitates the use of tailored machinery that aligns with specific operational needs. Custom machines can be designed to comply with stringent regulations while optimizing safety and performance. As global markets continue to expand, investing in tailored solutions will empower businesses to secure a competitive edge and respond proactively to industry changes, ensuring sustained growth in an increasingly dynamic landscape.