Unlocking the Advantages of Metal Parts Machine in Modern Manufacturing

In the evolving landscape of modern manufacturing, the integration of advanced technologies has become paramount for enhancing efficiency and precision. One critical innovation is the Metal Parts Machine, which plays a pivotal role in streamlining production processes across various industries. According to a recent report by MarketsandMarkets, the global metal fabrication market is projected to reach approximately $20.5 billion by 2026, driven largely by the demand for high-precision metal components. These machines not only improve production speed but also significantly reduce material waste, addressing one of the industry's pressing challenges: cost efficiency. Furthermore, the adoption of Metal Parts Machines fosters enhanced customization and flexibility, enabling manufacturers to meet the increasingly complex demands of today's customers. As the manufacturing sector continues to grapple with issues related to speed, quality, and cost, the benefits unlocked by Metal Parts Machines are proving indispensable for staying competitive in the market.

Understanding the Role of Metal Parts Machines in Contemporary Production Processes

The role of metal parts machines in contemporary production processes is increasingly vital as industries seek greater efficiency and precision. According to a report by MarketsandMarkets, the global market for advanced metal manufacturing machinery is projected to reach $89.5 billion by 2027, growing at a CAGR of 5.4% from 2022. This growth is driven by the demand for complex components in sectors like aerospace, automotive, and electronics, where traditional manufacturing methods often fall short.

Metal parts machines, such as CNC machining centers and additive manufacturing systems, enhance production capabilities by offering high accuracy and flexibility. A study by the National Institute of Standards and Technology (NIST) highlighted that CNC machining reduces production time by up to 75% compared to manual processes, while improving consistency and reducing waste. The integration of these machines not only streamlines workflows but also enables manufacturers to adapt quickly to changing market demands, fostering innovation and driving competitive advantage in today’s fast-paced industrial landscape.

Unlocking the Advantages of Metal Parts Machine in Modern Manufacturing

| Dimension | Value |

|---|---|

| Production Speed (units/hour) | 250 |

| Energy Efficiency (%) | 85 |

| Maintenance Cost ($/year) | 1200 |

| Material Waste Reduction (%) | 30 |

| Worker Safety Rate (%) | 95 |

| Setup Time (minutes) | 15 |

Key Benefits of Integrating Metal Parts Machinery in Manufacturing Systems

In today's rapidly evolving manufacturing landscape, the integration of metal parts machinery has become essential for businesses aiming to enhance productivity and efficiency. One of the key benefits is the precision offered by modern metalworking machines. These machines utilize advanced technologies such as CNC (Computer Numerical Control) and robotics, allowing for the production of intricate parts with tight tolerances. This level of precision not only reduces waste but also minimizes the need for extensive quality control, streamlining operations.

Additionally, investing in metal parts machinery can significantly improve the speed of production. Automated systems can operate continuously, handling high volumes of work without sacrificing quality. This capability not only accelerates turnaround times for orders but also allows manufacturers to respond swiftly to market demands. Furthermore, the consistency in output achieved through automation leads to improved reliability, fostering stronger relationships with clients who depend on timely delivery and uniform quality of products. By embracing the advantages of metal parts machinery, manufacturers position themselves for sustained growth and competitiveness in the global market.

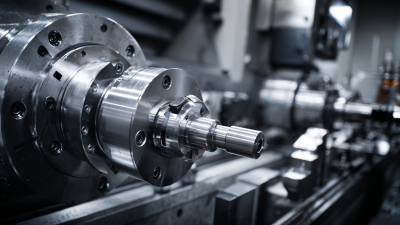

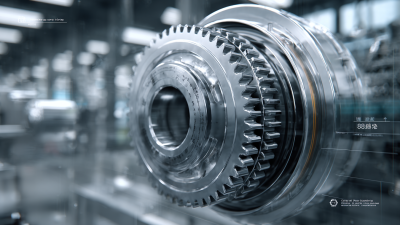

Types of Metal Parts Machines: An Overview of Available Technologies

In the realm of modern manufacturing, the evolution of technology has paved the way for various types of metal parts machines. From CNC (Computer Numerical Control) machines to laser cutters, each technology brings unique advantages that cater to different production needs. CNC machines, for instance, are renowned for their precision and ability to create complex geometries, making them indispensable for industries requiring high accuracy.

Tip: When selecting a metal parts machine, consider your production volume and the complexity of the parts you need. This will help you choose a technology that aligns with your operational goals and budget.

Another prominent technology is additive manufacturing, commonly known as 3D printing. This method enables the creation of intricate designs without the need for extensive tooling. It is particularly advantageous for prototyping and small batches where flexibility is crucial. Additionally, laser cutting has gained popularity due to its speed and the clean edges it produces, which minimize the need for additional finishing processes.

Tip: Always evaluate the material compatibility with the chosen machine. Different machines perform better with specific materials, so ensure you select one that suits your projects to maximize efficiency and quality.

Enhancing Precision and Efficiency with Metal Parts Manufacturing Equipment

The advancement of metal parts manufacturing equipment is pivotal in enhancing precision and efficiency across modern manufacturing sectors. With the global machine tool market projected to grow from $13.63 billion in 2025 to $22.946 billion by 2032, reflecting a compound annual growth rate (CAGR) of 8.1%, it is evident that industries are increasingly investing in sophisticated machinery to meet the rising demands for accuracy in production processes.

Cutting, machining, and welding equipment play crucial roles in this evolution, enabling manufacturers to execute intricate designs and achieve tighter tolerances that were previously unattainable.

Moreover, the metal fabrication equipment sector is also responding to sustainability trends, with technological innovations driving growth. The metal forging market is expected to expand significantly, largely fueled by increased emphasis on green manufacturing practices.

As companies seek to adapt to market changes and sustainability goals, the demand for advanced equipment not only facilitates better performance but also supports eco-friendly initiatives. With the continuous integration of technologies such as liquid metal 3D printing and laser welding, the prospects for enhanced precision and efficiency in metal part manufacturing are brighter than ever.

Future Trends in Metal Parts Machines and Their Impact on Industry

The manufacturing industry is on the brink of a transformative era, driven by advancements in metal parts machines. As we look towards the future, these machines are set to redefine the landscape of production, enhancing efficiency and precision in metalworking processes. The integration of smart technologies, such as IoT and AI, will enable manufacturers to optimize operations through real-time data analysis and automated adjustments, leading to reduced downtime and increased productivity.

Moreover, the upward trend in the use of advanced forging techniques within the metal parts sector reflects a broader move towards sustainability and resource efficiency. This shift not only addresses the environmental concerns but also aligns with the industry's push for high-quality, durable components. The adoption of sophisticated machinery tailored for specific production needs signifies the commitment to innovation, ensuring that manufacturers remain competitive. As the demand for customized metal parts escalates, these machines will play a crucial role in meeting customer specifications and achieving high standards in defense and industrial applications.

Related Posts

-

How to Choose the Best Metal Parts Machine for Your Manufacturing Needs

-

How to Optimize Production Efficiency for Metal Parts Machine

-

10 Essential Tips for Sourcing the Best Service Machine for Your Business

-

Exploring Innovative Alternatives to the Best Industrial Packing Machine

-

Maximizing Efficiency with Best Parts For Machine in Automotive Manufacturing Processes

-

Top Strategies for Sourcing the Best Welding Machines in the Global Market