Unique Challenges with the Best Machine Repairing Machine

As the industrial landscape evolves, the demand for efficient and reliable machinery continues to grow, bringing to the forefront the unique challenges associated with the "Machine Repairing Machine." By 2025, the market for these innovative solutions is projected to expand significantly, reflecting the increasing complexity of modern manufacturing processes. This blog will delve into the critical aspects of the Machine Repairing Machine—examining its impact on operational efficiency, maintenance costs, and overall productivity within various industries. We will also explore real-world examples that highlight the effectiveness of these machines in addressing mechanical failures, rejuvenating production lines, and fostering a culture of preventive maintenance. Join us as we navigate the intricacies of this essential technology and its promising role in shaping the future of industry.

Essential Factors to Consider When Selecting a Machine Repairing Machine

When selecting a machine repairing machine, several essential factors must be taken into account to ensure optimal performance and reliability. Firstly, the machine's compatibility with the specific types of equipment you intend to repair is crucial. Different machines have unique requirements in terms of size, shape, and operational features. It's important to evaluate whether the repairing machine can handle these factors efficiently.

Another significant consideration is the machine's durability and maintenance needs. Investing in equipment that is robust and requires minimal upkeep will not only enhance productivity but also reduce long-term costs. Users should look for machines that offer user-friendly maintenance protocols and readily available replacement parts. Additionally, the technological advancements embedded in the repairing machine, such as automation capabilities and user interfaces, can dramatically affect operational efficiency. Opting for a machine with modern features can streamline the repair process, mitigate human error, and improve overall output quality.

Common Technical Challenges Faced in Machine Repairs and Maintenance

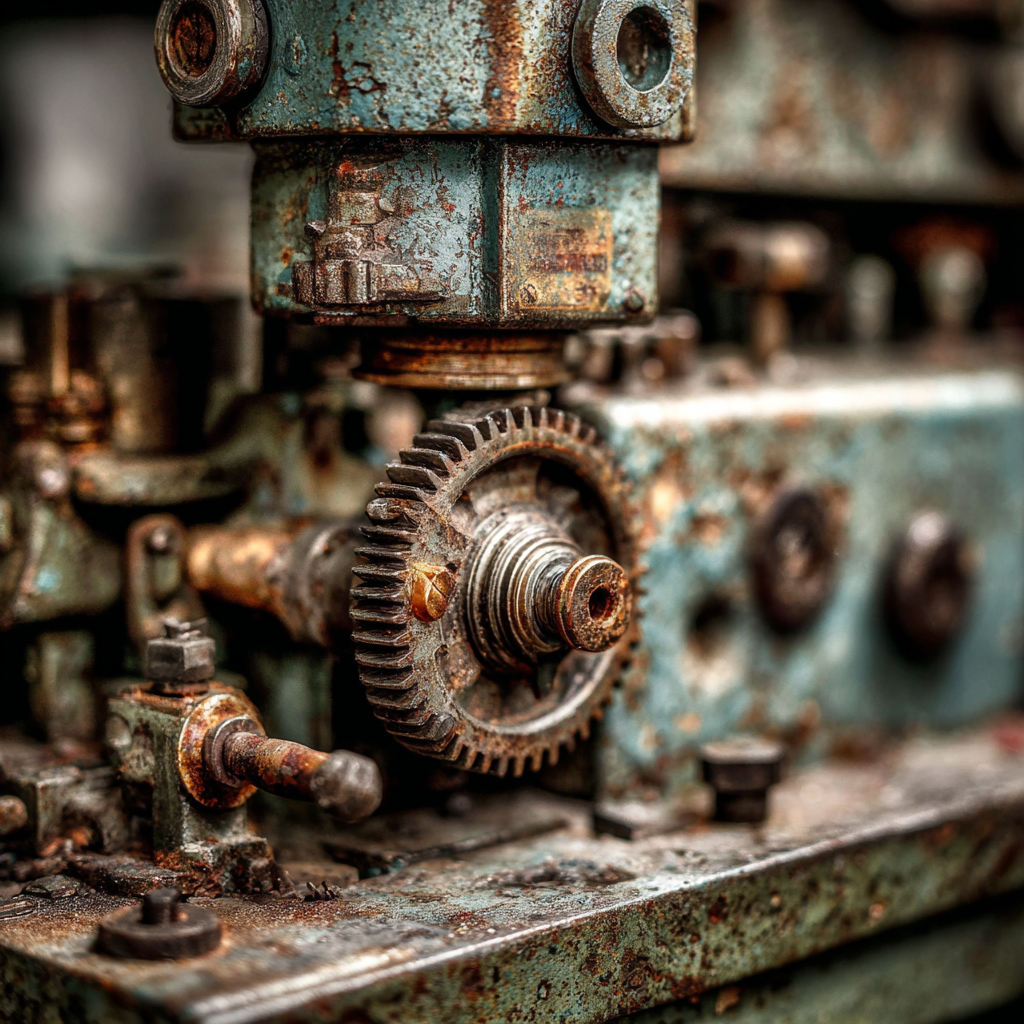

In the realm of machine repairs and maintenance, various technical challenges frequently hinder operational efficiency. According to a report by the National Center for Manufacturing Sciences, about 30% of maintenance issues stem from inadequate training of repair staff. This lack of expertise can lead to extended downtime, resulting in significant production losses. Complex machinery often demands a deep understanding of its components and functions, making it essential for technicians to receive ongoing education and hands-on training.

Another pressing challenge is the rapid pace of technological advancement. A study by the International Society of Automation indicates that nearly 50% of industrial manufacturers face difficulties in integrating new technologies into their existing systems. This integration often requires a reevaluation of maintenance protocols and equipment, which can be resource-intensive. Additionally, with the rise of predictive maintenance technologies, companies must adapt their repair strategies to utilize data analytics effectively, ensuring they can anticipate failures before they occur.

Addressing these technical hurdles is critical for optimizing machine performance and minimizing costly downtimes.

The Importance of Regular Maintenance Checklists for Machine Repairing Machines

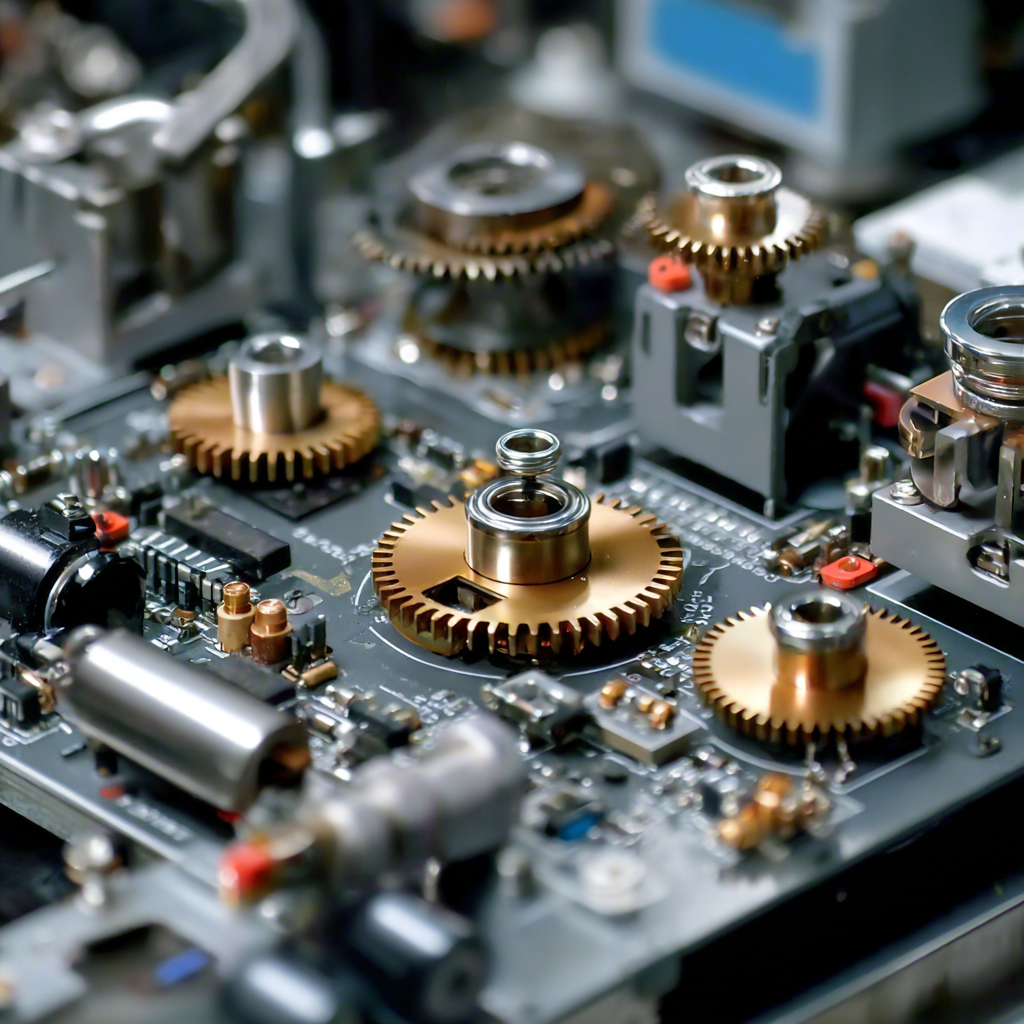

Regular maintenance is paramount when it comes to machine repairing machines. These specialized tools play a crucial role in ensuring that other machinery remains operational. A well-structured checklist can help identify potential issues before they escalate, safeguarding both the equipment and the workers. By systematically reviewing components such as belts, motors, and electronic circuits, engineers and technicians can ensure that each machine operates at its optimal level.

Regular maintenance is paramount when it comes to machine repairing machines. These specialized tools play a crucial role in ensuring that other machinery remains operational. A well-structured checklist can help identify potential issues before they escalate, safeguarding both the equipment and the workers. By systematically reviewing components such as belts, motors, and electronic circuits, engineers and technicians can ensure that each machine operates at its optimal level.

Furthermore, adherence to a maintenance checklist fosters a culture of safety and efficiency. It encourages the team to stay vigilant and proactive, reducing the risk of unexpected breakdowns that could lead to costly downtime. The complexity of machine repairing machines means that even minor oversights can result in significant problems, making routine inspections and checklists not just helpful, but essential. Regularly updating these checklists based on observed wear and tear can enhance the longevity and performance of the machines, thus maximizing return on investment for businesses reliant on these vital tools.

Innovative Features to Look for in Modern Machine Repairing Machines

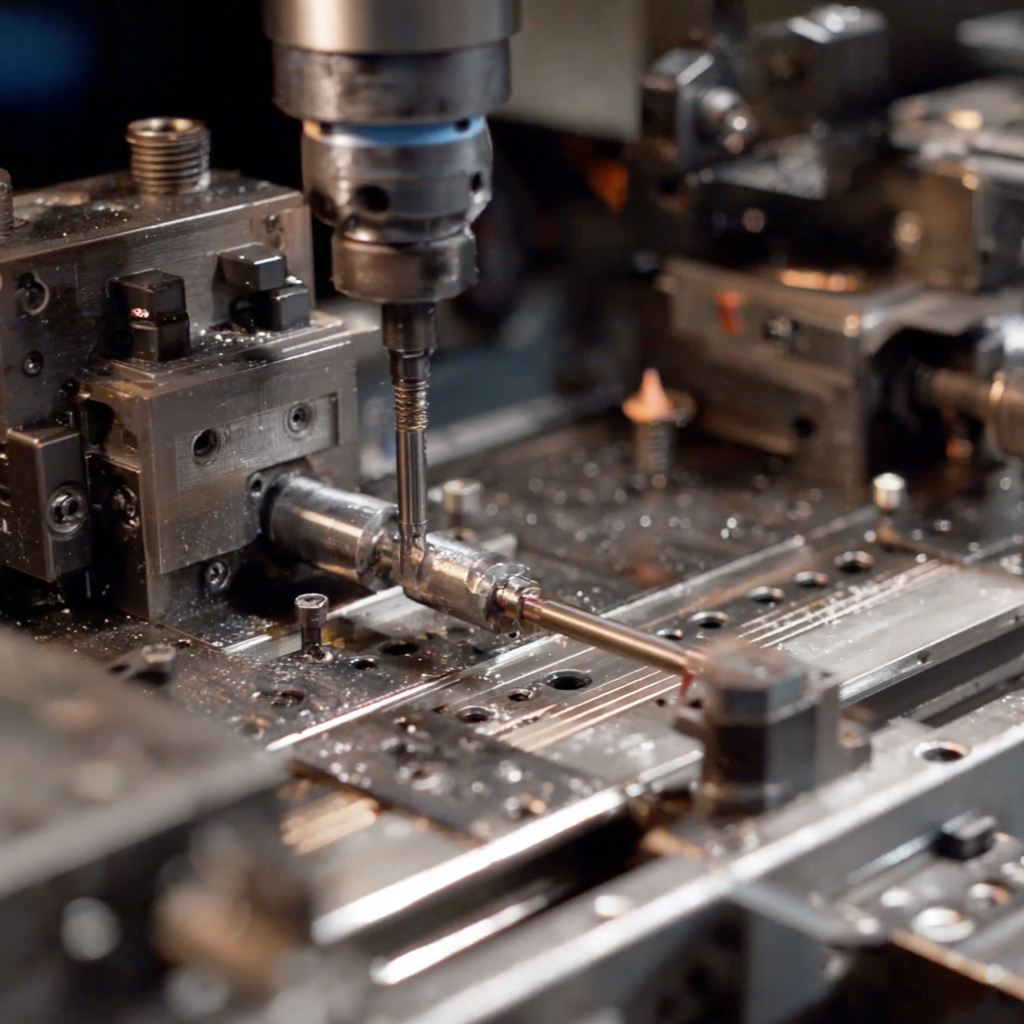

When considering the latest advancements in machine repairing machines, it's essential to focus on innovative features that streamline the repair process. According to a recent report by the International Journal of Advanced Manufacturing Technology, machine downtime can lead to production losses estimated at around $50 billion annually. Thus, investing in modern repairing machines equipped with innovative technology can significantly mitigate these losses.

One of the key features to look for is intelligent diagnostics. These systems utilize artificial intelligence and machine learning algorithms to quickly identify malfunctions and suggest solutions, reducing repair time by up to 30%. Additionally, machines with advanced connectivity options, such as IoT capabilities, allow for remote monitoring and real-time data analysis, which enhances predictive maintenance. A report from McKinsey states that businesses implementing IoT in their machinery can improve operational efficiency by 10-20%, resulting in reduced repair costs and enhanced production uptime.

Furthermore, the introduction of modular designs in modern machine repairing machines facilitates easy upgrades and replacements, minimizing the need for complete overhauls. The flexibility of these machines allows for customized solutions tailored to specific industries, addressing unique challenges faced in different sectors. As companies prioritize operational efficiency, these innovative features become essential for maintaining competitive advantage in the rapidly evolving landscape of manufacturing.

Strategies to Combat Downtime During Machine Repair Processes

When it comes to machine repair processes, downtime can be one of the most daunting challenges for any business. The nuances of repairing sophisticated machinery require a strategic approach to mitigate the impact of these waiting periods. One effective strategy is to implement a proactive maintenance schedule. By routinely inspecting and maintaining equipment, businesses can identify potential issues before they escalate, thus significantly reducing the likelihood and duration of unexpected repairs.

Another critical element in combating downtime is enhancing communication within the repair team. Establishing clear channels for reporting issues and sharing updates can expedite decision-making processes. Utilizing technology such as real-time monitoring systems can allow teams to track machine performance, enabling faster diagnostic assessments and more efficient repairs. Furthermore, training staff to handle minor repairs and perform regular maintenance can empower them to resolve issues quickly and keep machines operational for longer periods, ultimately leading to increased productivity.