China's Pinnacle of Excellence: The Unmatched Best Machine Repairing Machine for Global Buyers

In an era where manufacturing efficiency and precision are paramount, the demand for advanced machinery continues to surge globally. According to a recent report by MarketsandMarkets, the global machine repair market is projected to reach $2.6 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.5%. Within this landscape, the significance of a superior "Machine Repairing Machine" has become increasingly evident. These innovative machines not only enhance the longevity of equipment but also reduce downtime and maintenance costs significantly. As global industries strive to optimize their operations, China's pinnacle of excellence in producing unmatched machine repairing machines stands out, catering to the diverse needs of international buyers. This blog will delve into the problems faced in the industry and how state-of-the-art solutions from China are addressing these challenges, paving the way for enhanced productivity across sectors.

In an era where manufacturing efficiency and precision are paramount, the demand for advanced machinery continues to surge globally. According to a recent report by MarketsandMarkets, the global machine repair market is projected to reach $2.6 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.5%. Within this landscape, the significance of a superior "Machine Repairing Machine" has become increasingly evident. These innovative machines not only enhance the longevity of equipment but also reduce downtime and maintenance costs significantly. As global industries strive to optimize their operations, China's pinnacle of excellence in producing unmatched machine repairing machines stands out, catering to the diverse needs of international buyers. This blog will delve into the problems faced in the industry and how state-of-the-art solutions from China are addressing these challenges, paving the way for enhanced productivity across sectors.

Global Overview of Machine Repairing Machines: The Rise of China's Innovation

In recent years, China's machine repairing machines have emerged as a beacon of innovation on the global stage. With advancements in engineering and automation, Chinese manufacturers have significantly enhanced the efficiency and reliability of machines designed for repair purposes. These cutting-edge technologies not only address the growing demand for machine upkeep but also cater to the specific needs of diverse industries worldwide. As global buyers seek dependable solutions, China's offerings stand out for their combination of affordability and high performance.

The rise of China's innovation in this sector reflects a broader trend of technological leadership. Chinese companies have invested heavily in research and development, resulting in machines that incorporate smart technologies and advanced materials. This focus on innovation has positioned China as a key player in the global market, as its machine repairing solutions empower businesses to minimize downtime and optimize productivity. As international customers increasingly recognize the value of these well-engineered machines, China's reputation for quality and innovation continues to solidify.

Key Features that Set China's Machines Apart from Competitors

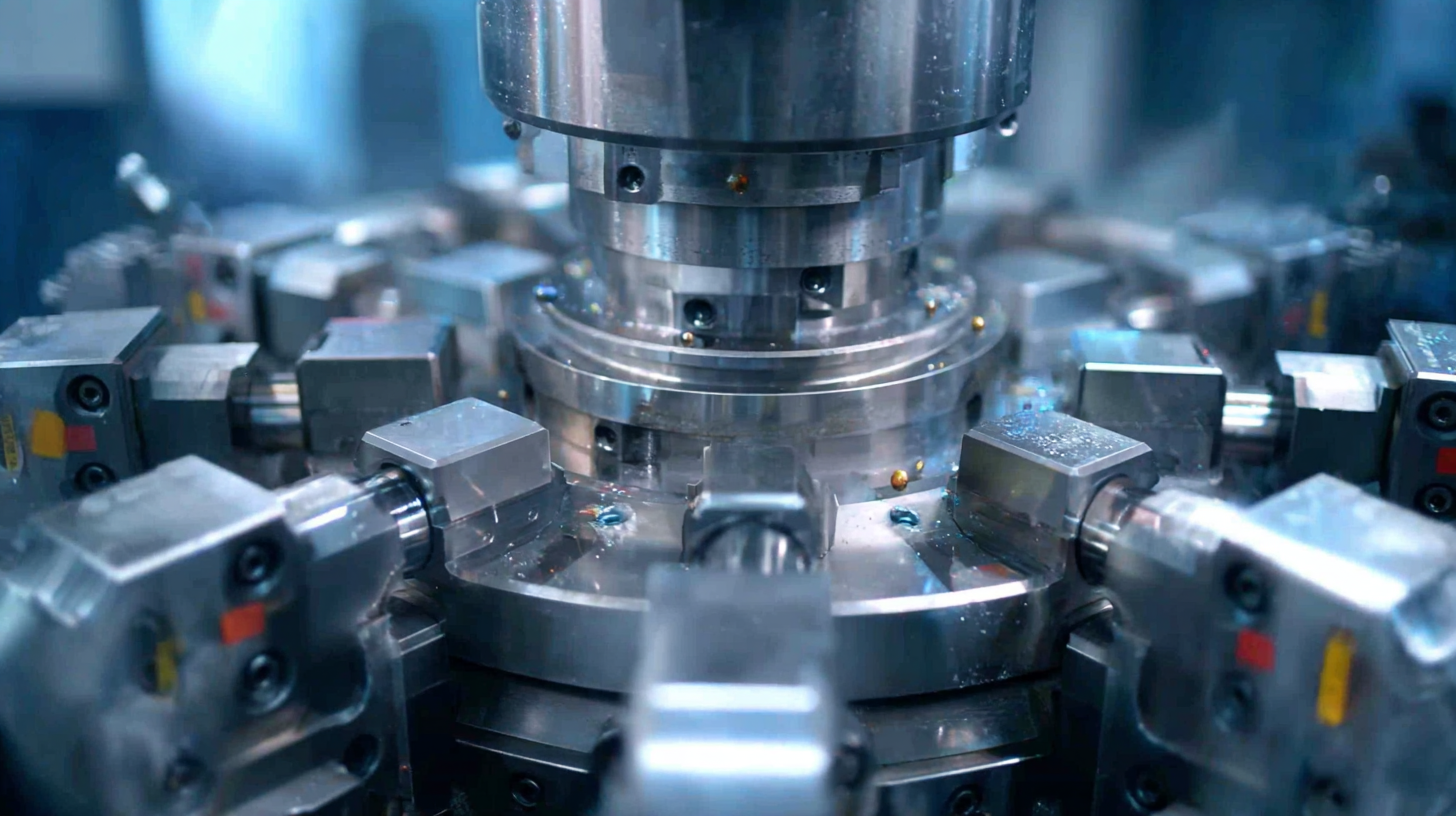

China's machine repairing machines stand out in the global market due to several key features that set them apart from their competitors. Firstly, the integration of advanced technology plays a crucial role. These machines often incorporate cutting-edge automation and artificial intelligence, allowing for precision repairs that enhance efficiency and reduce operational downtime. This technological edge not only improves performance but also ensures that these machines can handle a wide range of repair tasks with exceptional accuracy.

Secondly, the emphasis on durability and reliability cannot be overlooked. Chinese manufacturers typically utilize high-quality materials and rigorous testing protocols in their production processes. This commitment to excellence results in machines that are built to last, minimizing maintenance costs and extending their lifespan. Furthermore, the cost-effectiveness of these machines makes them an attractive choice for global buyers, as they combine superior performance with competitive pricing. The combination of advanced technology, durability, and affordability encapsulates why China's machine repairing machines are regarded as the pinnacle of excellence in the industry.

Comparative Analysis: Performance Metrics of Leading Machine Repairing Machines

In the ever-evolving world of industrial machinery, the performance metrics of machine repairing machines play a crucial role in determining their efficiency and reliability. A comparative analysis reveals that the leading models in the market today vary significantly in terms of speed, accuracy, and ease of use. While traditional models often fall short in handling complex repairs, the newest entrants boast advanced technology that dramatically reduces downtime, ensuring operations run smoothly. Features such as automated diagnostics and user-friendly interfaces are setting new standards for what can be expected from machine repair solutions.

Furthermore, performance metrics such as energy consumption and maintenance frequency present significant considerations for global buyers. Machines that provide higher efficiency while minimizing energy usage tend to yield greater long-term savings. Additionally, models designed with self-cleaning mechanisms and less frequent part replacements stand out for their lower ongoing maintenance costs. This comparative analysis not only highlights the critical factors buyers should consider but also emphasizes the importance of investing in technologically advanced machinery that aligns with the demands of modern manufacturing practices.

Cost vs. Value: An In-Depth Look at Pricing Strategies and Quality

In the competitive arena of machine repairing, understanding the balance between cost and value is crucial for buyers worldwide. While price is often the most immediate factor in decision-making, the value derived from a machine's performance, durability, and the service it provides is paramount. Many global buyers are increasingly looking beyond the initial expenditure to evaluate long-term benefits. The best machine repairing machines from China do not just promise efficiency but also deliver exceptional quality that results in lower operational costs over time.

Price strategies in the machine repair sector vary significantly, reflecting the diverse needs of global buyers. Some manufacturers adopt a low-cost approach, aiming to capture a wider market share, while others focus on high-end machines that emphasize advanced technology and superior craftsmanship. It is essential for buyers to analyze these pricing strategies relative to the proposed quality. In doing so, they can avoid the pitfalls of opting for cheaper alternatives that may lead to excessive downtimes and costly repairs, ultimately detracting from the overall value of their investment.

China's Pinnacle of Excellence: The Unmatched Best Machine Repairing Machine for Global Buyers - Cost vs. Value: An In-Depth Look at Pricing Strategies and Quality

| Machine Type | Average Price (USD) | Repair Efficiency (%) | Warranty Period (Years) | Customer Satisfaction (%) |

|---|---|---|---|---|

| High-Precision Lathe | $15,000 | 92 | 3 | 95 |

| CNC Milling Machine | 20,000 | 85 | 2 | 90 |

| Hydraulic Press | 25,000 | 87 | 4 | 92 |

| Laser Cutting Machine | 30,000 | 90 | 5 | 97 |

| Robotic Arm | 50,000 | 88 | 3 | 94 |

Customer Testimonials: Real-World Experiences with China's Best Machines

When it comes to machine repair, China has truly set the bar high with its unmatched machines that cater to global buyers. Customer testimonials illuminate the reliable performance and advanced technology embedded in these machines, shedding light on real-world experiences that showcase their effectiveness. One customer from Germany shared how the precision of the machine not only improved operational efficiency but also drastically reduced downtime, allowing their business to flourish. Such enthusiastic feedback emphasizes the commitment to quality that Chinese manufacturers uphold.

Another user from Brazil highlighted the seamless integration of these machines into their existing workflow, underscoring the user-friendly design that accommodates varying skill levels. The support and training provided were praised as well, making the transition smooth and productive. These firsthand accounts serve as a testament to China’s dedication to innovation in machine repair technology, helping businesses across the globe achieve their operational goals with ease.