Why Choose a Machine Welding Machine for Your Industrial Needs

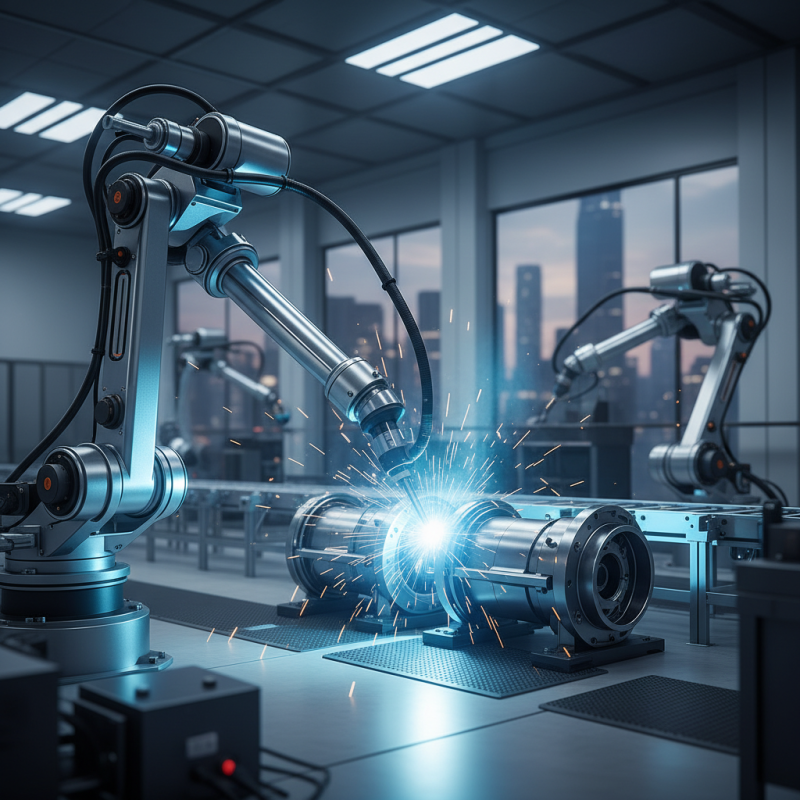

In today's competitive industrial landscape, the choice of equipment can significantly influence productivity and efficiency. One of the key innovations that have emerged is the Machine Welding Machine, which offers unparalleled precision and consistency in manufacturing processes. According to a recent report by the International Welding Institute, the market for welding technology is expected to reach $30 billion by 2025, reflecting a growing recognition of the importance of advanced welding solutions across various sectors. This trend underscores the necessity for industries to invest in modern machinery that enhances operational capabilities.

Dr. James K. Thompson, an expert in welding technology and a leading figure in the field, emphasizes the value of these machines by stating, "Implementing a Machine Welding Machine is not just about upgrading equipment; it's about revolutionizing production potential." His insights highlight the significance of these advanced machines in improving not only the quality of welds but also in reducing operational costs and time. As industries strive to meet increasing demands for efficiency and quality control, the adoption of Machine Welding Machines could prove to be a transformative step toward achieving those goals.

Advantages of Machine Welding Machines in Industrial Applications

Machine welding machines have become indispensable tools in various industrial applications, offering numerous advantages that enhance efficiency and productivity. One of the primary benefits of using machine welding is the consistency it provides. Unlike manual welding, which relies on the skills of the operator, machine welding ensures uniform quality across every weld, minimizing the chances of defects and rework. This standardization not only boosts the reliability of welded structures but also optimizes material use, reducing waste.

In addition to consistency, machine welding machines can significantly improve operational speed. These machines are designed to operate at optimal speeds, allowing industries to complete projects more quickly than manual methods would permit. As a result, businesses can meet tight deadlines and increase their throughput without compromising on quality. Furthermore, automation in welding reduces the physical strain on workers, leading to a safer work environment and potentially lowering labor costs.

Tips: When transitioning to a machine welding setup, ensure proper training for employees to maximize the efficiency and safety of these machines. Regular maintenance checks are also crucial to sustain performance and prevent breakdowns, keeping production timelines intact. Lastly, evaluating the workload and selecting the right type of machine welding for specific applications can greatly enhance overall productivity.

Types of Machine Welding Machines and Their Specific Uses

When selecting a machine welding machine for industrial applications, it's essential to understand the various types available and their specific uses. One common type is the MIG (Metal Inert Gas) welder, which is suitable for beginners due to its ease of use and versatility. It's ideal for welding thin sheets of metal and is widely used in automotive and general manufacturing industries. The MIG welder can produce clean and strong welds quickly, making it a favorite for both small and large-scale projects.

Another popular option is the TIG (Tungsten Inert Gas) welder, known for its precision and ability to weld a range of metals, including aluminum and stainless steel. This type of welding is often utilized in applications where aesthetics and weld quality are paramount, such as in fabricating art pieces or custom metal components. TIG welding requires a higher skill level but produces some of the cleanest welds possible.

Tip: When choosing a welding machine, consider the thickness and type of materials you will be working with. Understanding the specific requirements of your projects will help you select the right equipment for optimal results.

Stick welding machines are also essential, particularly for heavy-duty applications. They are robust and effective for welding in outdoor conditions and can be used on rusty or contaminated surfaces. Stick welders are commonly found in the construction industry.

Tip: Always wear appropriate safety gear, such as gloves and goggles, to protect yourself from sparks and UV radiation when welding.

Types of Machine Welding Machines and Their Specific Uses

Key Features to Consider When Choosing a Machine Welding Machine

When selecting a machine welding machine for industrial applications, several key features must be considered to ensure optimal performance and efficiency.

First and foremost, the power capacity of the machine is critical; it should match the material thickness and type being welded.

According to a report by the International Institute of Welding, the right power output can significantly reduce welding defects, leading to approximately a 20% increase in production efficiency for businesses that prioritize proper equipment matching.

Another vital feature is the welding process compatibility. Different processes, such as MIG, TIG, or Stick welding, possess distinct advantages depending on the specific industrial requirements.

A study conducted by the Manufacturing Institute indicates that companies utilizing multi-process welding machines reported a 30% improvement in versatility and productivity, allowing operators to switch between processes without the need for multiple machines.

Additionally, consider the machine's automation capabilities. Advanced machines equipped with automated features not only enhance precision but also mitigate the risk of human error.

Research published in the Journal of Manufacturing Science and Engineering highlights that automation can lead to a reduction in production time by up to 40%, granting manufacturers a competitive edge in a time-sensitive market.

Overall, evaluating these key features will empower businesses to choose a machine welding machine that aligns with their operational goals and enhances overall productivity.

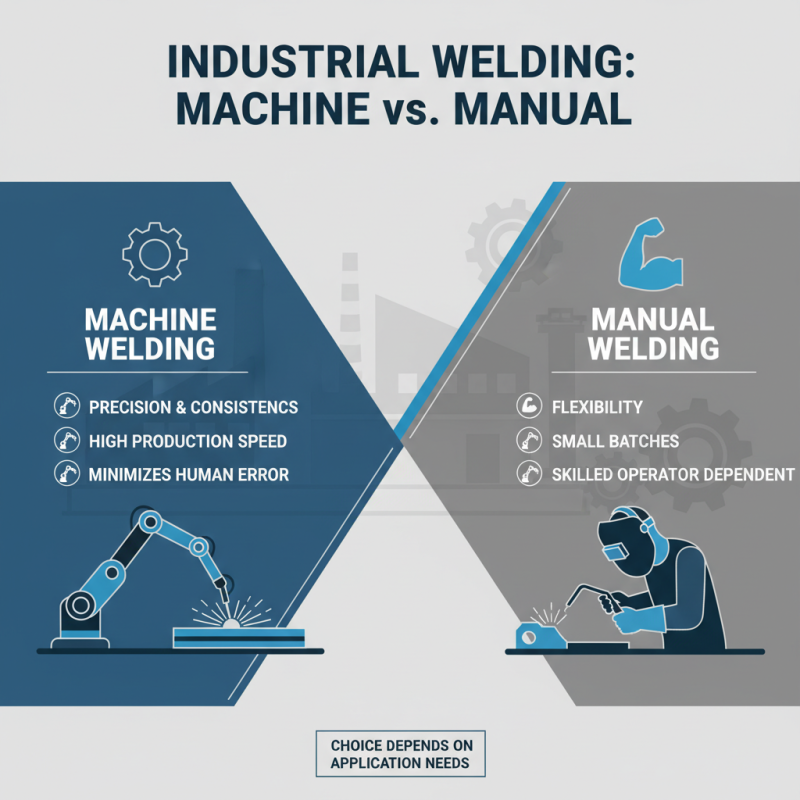

Comparative Analysis: Machine Welding vs. Manual Welding Techniques

When considering welding techniques for industrial applications, the choice between machine welding and manual welding is critical. Machine welding, typically automated, offers precision and consistency that manual techniques struggle to match. In environments where high production speeds and uniform quality are essential, machine welding minimizes the risk of human error, ensuring each weld meets stringent specifications. The automated process also facilitates the handling of complex geometries and repetitive tasks, making it ideal for large-scale manufacturing settings.

On the other hand, manual welding retains its importance in scenarios requiring flexibility and skill. Skilled welders can adapt quickly to variations in materials, settings, and designs that an automated process might struggle to accommodate. Manual welding also allows for detailed finishing work that can enhance the aesthetic quality of welded components. For industries where artistic craftsmanship or intricate designs are paramount, manual techniques provide a level of control that machines cannot replicate. Ultimately, the decision between machine and manual welding should be guided by specific project requirements, balancing the need for precision and efficiency against the demand for flexibility and creativity.

Cost-Benefit Evaluation of Investing in Machine Welding Technology

Investing in machine welding technology offers substantial cost benefits for industrial operations. According to a report by the International Federation of Robotics, automated welding systems can increase productivity by up to 30% compared to manual welding operations. This enhancement not only accelerates production cycles but also reduces labor costs, leading to a faster return on investment. Additionally, the reduction in human error associated with machine welding results in higher quality welds, which can decrease the amount of rework and material waste, further contributing to cost savings.

Furthermore, machine welding technologies often come with advanced features such as real-time monitoring and adjustments, which can enhance operational efficiency. A study published by the American Welding Society indicates that companies that adopt robotic welding report a decrease in operational costs by approximately 20% over three years. This reduction is largely attributed to lower energy consumption and minimized downtime due to the reliability of automated systems. As industries continue to evolve, the long-term financial benefits of integrating machine welding technology become increasingly clear, positioning companies to remain competitive in a fast-paced market.

Related Posts

-

Exploring the Future of Machine Welding Machines in Modern Manufacturing Techniques

-

Elevate Your Operations with the Best Welding Machines Made in China for Global Markets

-

Top Strategies for Sourcing the Best Welding Machines in the Global Market

-

Unlocking the Advantages of Metal Parts Machine in Modern Manufacturing

-

5 Essential Tips to Choose the Best Commercial Machine for Your Business Growth

-

2025 Top 5 Industrial Packing Machines You Need to Know