How to Choose the Best Industrial Milling Machine for Your Needs

Choosing the best industrial milling machine for your specific needs is a crucial decision that can significantly affect the efficiency and productivity of your operations. As John Smith, a renowned expert in industrial manufacturing, once stated, "The right milling machine can transform your production capabilities, enabling precision and scalability that are essential in today's competitive market." Understanding the diverse range of options available and the distinct features that each machine offers is vital for making an informed choice.

In an industry where precision and reliability are paramount, the selection process becomes even more critical. Industrial milling machines vary in size, functionality, and price, making it essential to assess your unique requirements before making a purchase. Factors such as the materials you'll be working with, the level of complexity in the projects you undertake, and your budget all play a significant role in determining the ideal milling machine for your operations. By considering these elements carefully, you can ensure that you select a machine that aligns perfectly with your manufacturing goals.

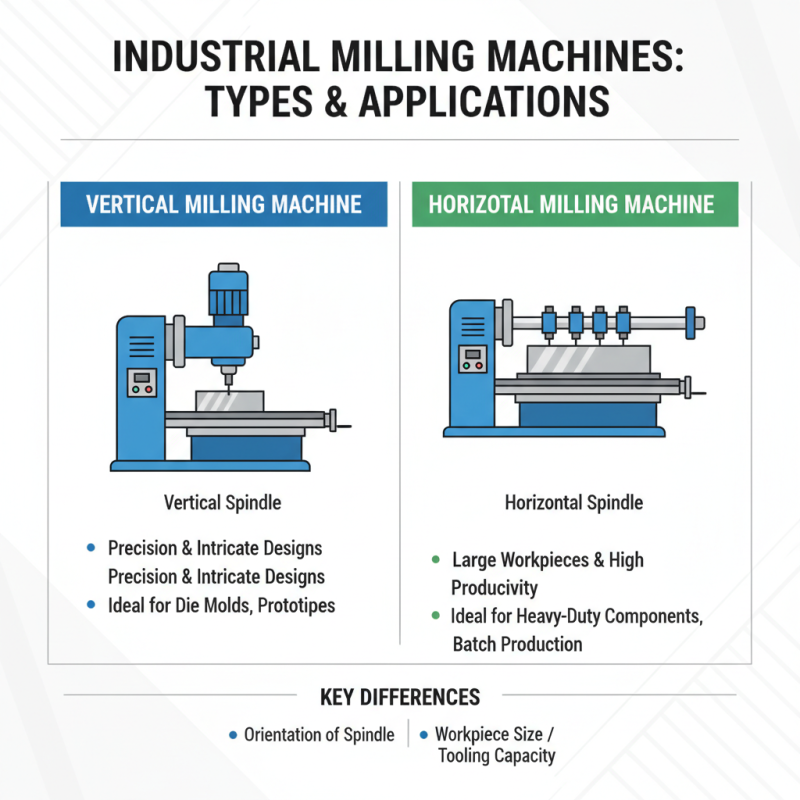

Understanding the Different Types of Industrial Milling Machines

When selecting an industrial milling machine, understanding the various types available can significantly influence your decision. Primarily, milling machines can be categorized into two main types: vertical and horizontal. Vertical milling machines have a vertically oriented spindle, which allows for the cutting tool to be positioned directly over the workpiece, making them ideal for precision work and intricate designs. On the other hand, horizontal milling machines utilize a horizontal spindle, providing better control over larger workpieces and enabling the use of multiple cutting tools simultaneously, thereby increasing productivity in various operations.

Additionally, there are specialized types of milling machines designed for specific tasks. For instance, CNC (Computer Numerical Control) milling machines offer enhanced precision and automation, allowing for complex designs to be executed with minimal human intervention. Another type is the bed mill, which is characterized by its stationary bed and a movable spindle, suitable for heavy-duty tasks. Understanding these distinctions is crucial, as each type serves different operational needs, from general machining to specialized manufacturing processes. By considering the specific requirements of your projects, you can choose the milling machine that best fits your operational demands.

Key Factors to Consider When Selecting a Milling Machine

When selecting an industrial milling machine, several key factors must be taken into account to ensure it aligns with your operational needs. First and foremost, consider the machine's size and capacity. Assess the types of materials you will be working with, as well as the size of the workpieces. This will help you determine the appropriate bed size and spindle capabilities necessary for efficient processing. Additionally, the machine's power output plays a vital role in its performance, as higher horsepower can translate to faster cutting speeds and improved productivity.

Another critical factor is the machine's ease of use and maintenance. Look for features that enhance user-friendliness, such as intuitive controls and automated functionalities, which can significantly reduce the learning curve for operators. Maintenance requirements should also be evaluated; machines that are easier to service can minimize downtime and prolong the lifespan of the equipment. Moreover, consider the level of technical support and availability of spare parts that a manufacturer offers, as this can impact the reliability of the milling machine in your production environment.

Factors to Consider When Choosing an Industrial Milling Machine

This chart illustrates key factors to consider when selecting an industrial milling machine, with their importance rated from 1 to 10. Power and speed are critical, whereas price has a lower significance compared to other factors.

Assessing the Required Features and Specifications

When selecting an industrial milling machine, assessing the required features and specifications is crucial to ensuring that it meets your operational needs. First, consider the size and capacity of the machine. The workpiece size you intend to mill directly influences the machine dimensions and its load capacity. For larger projects or heavy materials, you may need a machine with a more substantial framework and higher motor power. Additionally, evaluate the spindle speed and feed rate options; these parameters affect the machining speed and precision, enabling you to achieve the desired surface finish and tolerances.

Another important factor to assess is the type of milling processes the machine supports. Some machines are designed for specific types of milling, such as face milling, end milling, or engraving, while others offer more versatile capabilities. Moreover, look into the tooling options available—whether the machine can accommodate various tools for different materials or specialized applications can significantly enhance productivity. Lastly, consider safety features, user interface, and maintenance requirements to ensure that the machine will not only perform effectively but also operate safely and efficiently within your facility.

How to Choose the Best Industrial Milling Machine for Your Needs - Assessing the Required Features and Specifications

| Feature | Specification | Importance |

|---|---|---|

| Cutting Speed | Up to 6000 RPM | High |

| Spindle Power | 5 HP to 20 HP | High |

| Table Size | Width: 200 mm - 1200 mm | Medium |

| Weight Capacity | 200 kg - 2000 kg | High |

| Control System | CNC or Manual | High |

| Material Compatibility | Metal, Plastic, Wood | Medium |

| Safety Features | Emergency Stop, Guards | High |

| Ease of Maintenance | Accessible Components | Medium |

Evaluating Budget and Cost-Effectiveness

When evaluating the budget and cost-effectiveness of industrial milling machines, it is crucial to balance initial investment with long-term operational costs. Start by assessing the machine's capabilities and the specific requirements of your operations. While a higher-priced machine may offer advanced features and better efficiency, it’s important to consider whether these benefits truly align with your production needs. Conducting a thorough cost analysis will help you estimate the total cost of ownership, including maintenance, repairs, and energy consumption over time.

Additionally, consider the resale value of the milling machine when making your decision. Some machines depreciate faster than others due to technological advancements or market demand. Investing in a model that retains its value can significantly offset your overall expenditure in the long run. It is equally important to review the warranty and support services offered to ensure that you are covered in case of any unforeseen issues, further contributing to the machine's cost-effectiveness. By carefully evaluating these factors, you can make a more informed decision that aligns with both your budget and operational efficiency.

Researching Brands and User Reviews for Reliability

When selecting the best industrial milling machine for your needs, prioritizing user reviews and brand reliability is crucial. User reviews serve as firsthand insights into the machine's performance, durability, and potential issues. By examining feedback from those who have used the milling machines in real-world applications, you gain valuable information about their reliability and the manufacturer's customer support. It’s important to focus on reviews that discuss long-term usage rather than just initial impressions to understand how the machine withstands day-to-day operations over time.

Additionally, researching brands can provide context to the user reviews. Established brands with a proven track record typically offer greater reliability and support structures for their products. Investigating how brands respond to criticism or technical issues raised by users can also reveal their commitment to customer satisfaction and product improvement. Reading through industry forums, asking fellow professionals, and compiling data from various sources can help you make an informed decision when selecting the right milling machine for your industrial needs.

Related Posts

-

2025 Trends: Unlocking the Secrets of the Best Industrial Milling Machines for Maximum Efficiency

-

How to Choose the Best Industrial Milling Machine for Your Business Needs

-

Exploring the Future of Industrial Milling Machines: Trends and Innovations Shaping Manufacturing in 2023

-

The Future of Advanced Milling Machine Technologies

-

7 Best Tips for Choosing the Right Milling Machine Machine for Your Business

-

How to Choose the Right Milling Machine for Your Business Needs