How to Choose the Best Metal Parts Machine for Your Manufacturing Needs

In the ever-evolving landscape of manufacturing, selecting the right Metal Parts Machine is crucial for optimizing production efficiency and ensuring product quality. As China leads the charge in top-tier manufacturing, its impact is felt globally with a strong export footprint that speaks to the ingenuity and precision of its machinery. With a plethora of options available, manufacturers must consider several factors, including the specific requirements of their production processes, material compatibility, and technological capabilities of the equipment. This blog will guide you through the essential criteria for choosing the best Metal Parts Machine tailored to your manufacturing needs, enabling you to leverage China's advanced machinery to enhance your production capabilities and maintain a competitive edge in the market.

Factors to Consider When Selecting Metal Parts Machines for Your Business

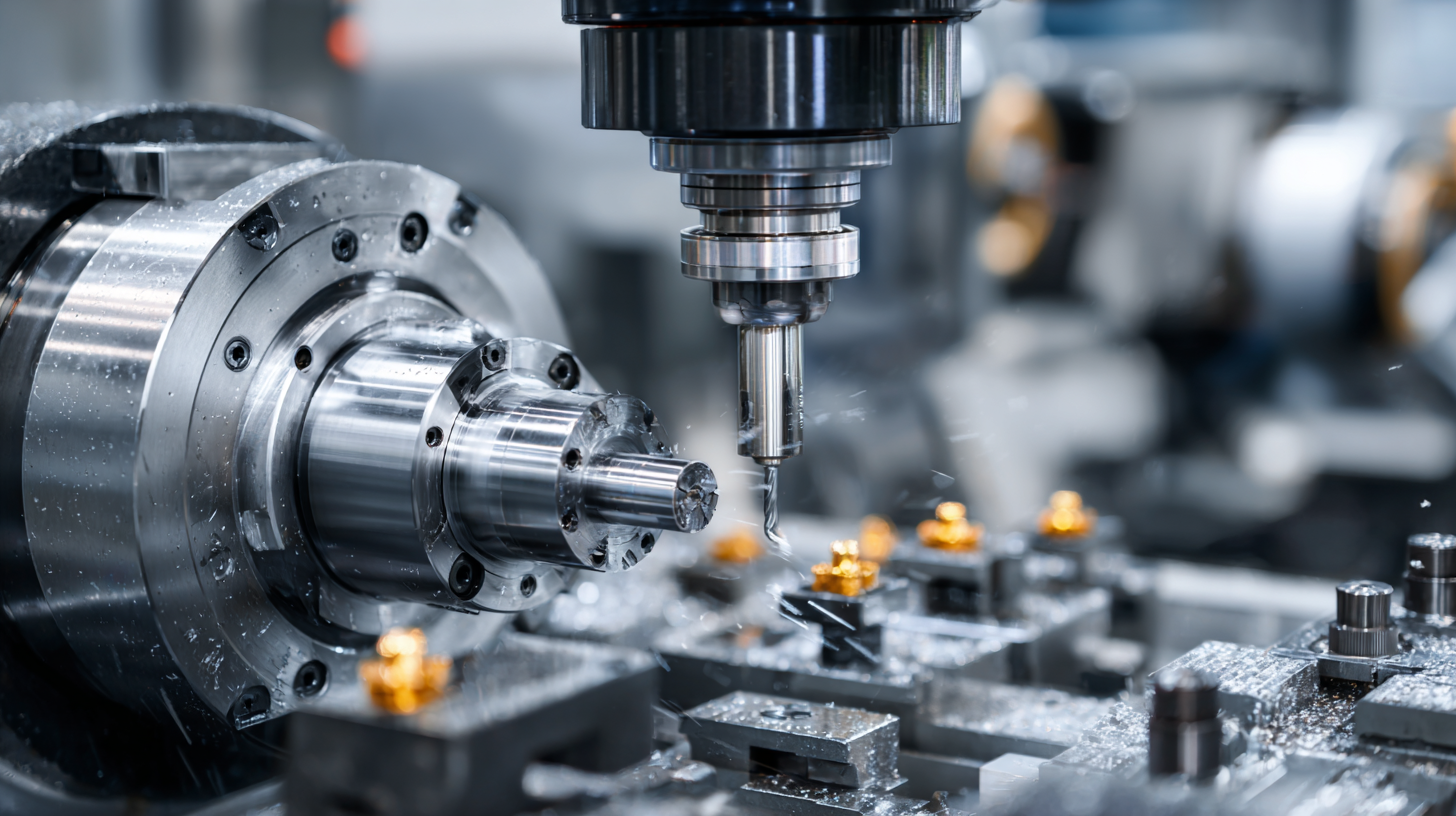

When selecting metal parts machines for your manufacturing needs, several crucial factors warrant consideration. First, assess the machine's capability to meet your specific production requirements, such as size, complexity, and material type. The shot blasting machine market exemplifies this, projected to grow from $1.41 billion in 2025 to $2.22 billion by 2032, highlighting increasing demand for efficient surface treatment solutions. Understanding the technology's compatibility with your existing processes can significantly influence operational efficiency.

**Tip:** Conduct a thorough analysis of the machine’s specifications and how they align with your operational goals. Engage with suppliers to gain insights into the latest advancements in machine technology, especially in innovative markets like China, where companies are rapidly evolving their manufacturing capabilities.

Next, don't overlook the long-term cost implications, including maintenance and training. Higher upfront investment might offer better efficiency or quality that pays off in the long run. The 2025 manufacturing industry outlook indicates that manufacturers will confront rising costs and uncertainties; thus, choosing machines that will sustain your business in fluctuating economic conditions is vital.

**Tip:** Utilize multi-criteria decision-making approaches to evaluate potential options comprehensively. Consider factors like energy consumption, support services, and scalability to ensure your investment yields maximum returns in the competitive landscape of manufacturing.

How to Choose the Best Metal Parts Machine for Your Manufacturing Needs

| Machine Type | Material Compatibility | Production Speed (units/hour) | Precision (mm) | Cost ($) |

|---|---|---|---|---|

| CNC Milling Machine | Aluminum, Steel | 50-300 | 0.01 | 20,000 |

| Laser Cutting Machine | Stainless Steel, Brass | 30-150 | 0.05 | 25,000 |

| Injection Molding Machine | Aluminum, Plastic | 100-800 | 0.1 | 50,000 |

| Waterjet Cutting Machine | Stone, Glass | 20-100 | 0.1 | 40,000 |

| 3D Metal Printer | Titanium, Aluminum | 5-20 | 0.02 | 80,000 |

Emerging Technologies Impacting Metal Parts Manufacturing in 2025

As we look towards 2025, the landscape of metal parts manufacturing is poised to undergo significant transformation driven by emerging technologies. Innovations such as additive manufacturing, advanced robotics, and artificial intelligence are set to reshape production processes, enhancing efficiency and precision. Additive manufacturing, in particular, offers the potential to reduce material waste and allow for the creation of complex geometries that were previously impossible with traditional machining methods. This shift not only streamlines production but also enables customizations that meet specific client demands.

Moreover, the integration of AI in manufacturing systems promises to optimize operations through smart analytics and predictive maintenance. AI algorithms can analyze data from various sources to predict equipment failures before they occur, thus minimizing downtime and maintenance costs. Coupled with the deployment of collaborative robots, or cobots, manufacturers will find themselves able to scale production while maintaining high standards of safety and quality. As these technologies continue to evolve, staying informed and adaptive will be crucial for businesses aiming to stay competitive in the metal parts manufacturing sector.

Emerging Technologies Impacting Metal Parts Manufacturing in 2025

Evaluating the Cost vs. Quality of Metal Parts Machines

When selecting a metal parts machine for manufacturing, understanding the delicate balance between cost and quality is crucial. Many manufacturers might be tempted to opt for the cheapest option available, but this can often lead to compromised quality in the final product.

High-quality machines often come with advanced technology and better materials, promising durability and reliability that lower-priced machines may lack. Investing in a high-quality machine may incur higher initial costs, but the potential for lower maintenance expenses and superior performance can often balance out the initial investment over time.

On the other hand, it’s essential to assess whether the premium features justify the price tag for your specific manufacturing needs. You should evaluate the machine's operational efficiency, accuracy, and the complexity of the parts you need to produce. If your production volume is high or your components require tight tolerances, then a higher-quality machine is likely worth the price for the benefits it brings, such as reduced waste and improved production speeds.

Thorough research and considering long-term operational costs versus upfront expenses will guide you to make a more informed decision that aligns with your manufacturing objectives.

The Role of Automation in Enhancing Manufacturing Efficiency

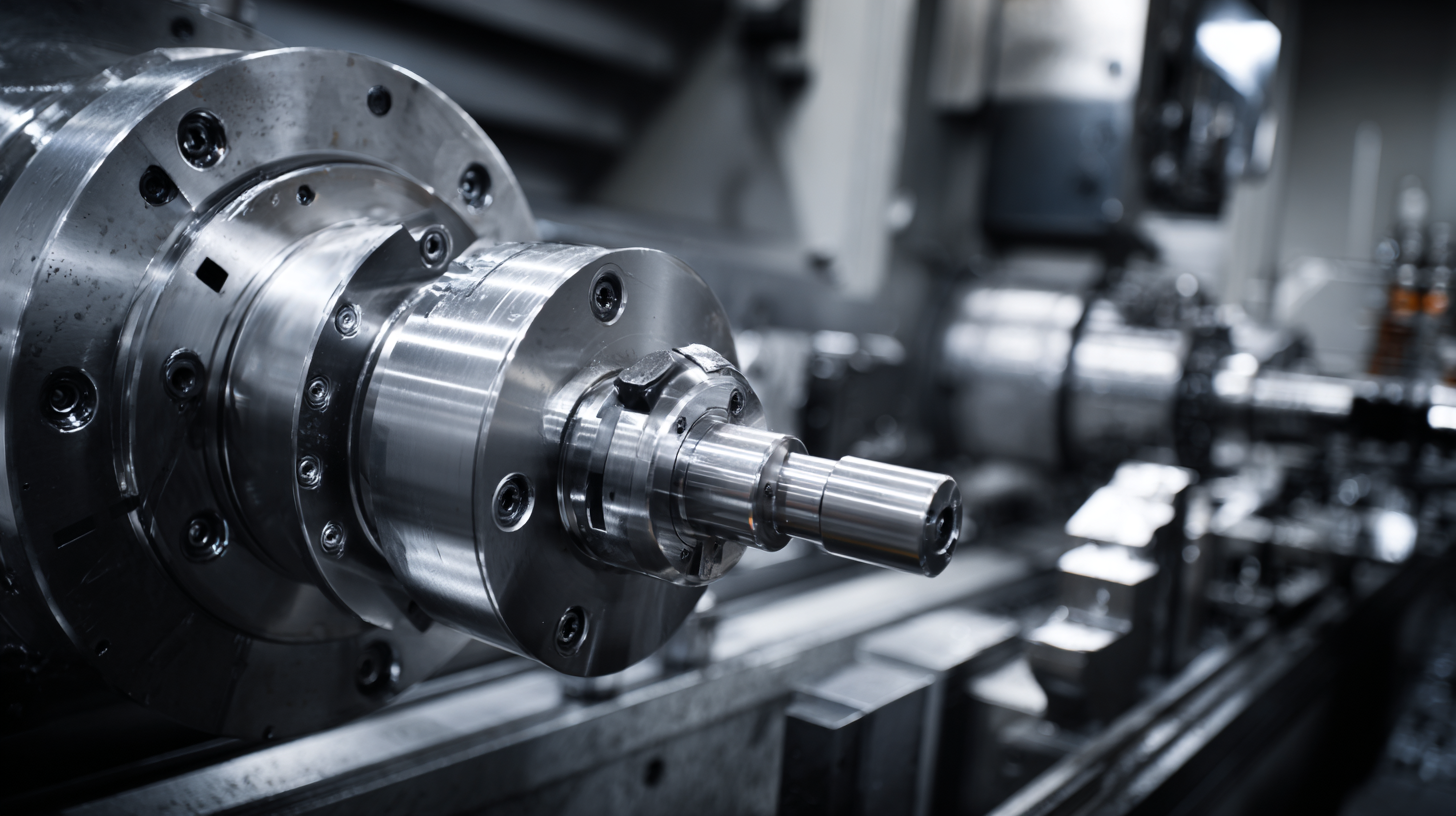

The role of automation in enhancing manufacturing efficiency is increasingly crucial as industries strive to improve productivity and accuracy. According to a report by McKinsey, automation can boost productivity in manufacturing by up to 30% by minimizing the reliance on manual labor and reducing the occurrence of human error. Automated machines not only streamline operations but also facilitate real-time monitoring, allowing manufacturers to quickly identify inefficiencies and make necessary adjustments.

Moreover, the adoption of automation technologies, such as robotics and AI-driven systems, has been shown to reduce production costs significantly. A study from Deloitte highlights that companies integrating automated processes have reported a reduction in operational costs by as much as 20%. This is particularly important in metal parts manufacturing, where precision and consistency are paramount.

As manufacturers increasingly embrace automation, they not only enhance their operational efficiency but also position themselves to meet the growing demands of a competitive market. The future of manufacturing undoubtedly hinges on the successful implementation of these advanced technologies.

Future Trends in Metal Parts Production Equipment and Their Implications

The landscape of metal parts production is rapidly evolving, driven by advancements in technology and shifting market demands. According to a recent report by Technavio, the global metal parts manufacturing market is expected to grow by over $300 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.2% from 2020. This growth is largely fueled by the increasing adoption of automation, artificial intelligence, and additive manufacturing techniques, which enhance efficiency, reduce lead times, and improve product quality.

One of the most significant trends shaping the future of metal parts production equipment is the rise of smart manufacturing technologies. Industry leaders are increasingly investing in IoT-enabled machines that allow for real-time monitoring and predictive maintenance, resulting in lower downtime and reduced operational costs. A study by the National Association of Manufacturers highlights that manufacturers who implement smart technologies can achieve up to a 20% increase in productivity. Moreover, the integration of sustainable practices is becoming imperative, as more companies aim to meet environmental regulations and consumer demand for greener products. As sustainability becomes a cornerstone of production, manufacturers are urged to consider machines that minimize waste and optimize energy consumption to stay competitive in this evolving market.