How to Choose the Right Milling Machine for Your Business Needs

Choosing the right milling machine for your business is crucial, as it directly impacts productivity, efficiency, and overall manufacturing costs. The global milling machine market was valued at approximately $73 billion in 2022 and is projected to grow at a CAGR of 7.8% over the next five years, according to a recent industry report. As manufacturers face increasing competition and demand for precision engineering, selecting a milling machine that aligns with specific business needs can enhance operational capabilities. Factors such as the type of materials processed, production volume, and desired tolerances must be considered to make informed decisions. With advancements in technology, modern milling machines offer enhanced versatility and automation, enabling businesses to optimize their processes and reduce waste. Thus, identifying the best milling machine not only facilitates superior manufacturing outcomes but also positions businesses for long-term success in a rapidly evolving market.

Factors to Consider When Selecting a Milling Machine for Optimal Performance

When selecting a milling machine for optimal performance, several key factors should be considered to ensure it meets your business needs efficiently. First, the type of materials you will be working with plays a crucial role. Different milling machines are designed to handle specific materials, whether it's metals, plastics, or wood. Understanding the hardness and thickness of the materials will help determine the appropriate machine specifications, such as spindle speed and cutting tools.

When selecting a milling machine for optimal performance, several key factors should be considered to ensure it meets your business needs efficiently. First, the type of materials you will be working with plays a crucial role. Different milling machines are designed to handle specific materials, whether it's metals, plastics, or wood. Understanding the hardness and thickness of the materials will help determine the appropriate machine specifications, such as spindle speed and cutting tools.

Additionally, the size and capability of the milling machine should align with your production requirements. Consider the machine's capacity in terms of workpiece size and weight, ensuring it can accommodate your typical projects. Furthermore, features such as automation, programmable controls, and ease of operation can significantly impact productivity and operator skill requirements. Evaluating these factors will help you select a milling machine that not only meets current demands but also allows for future growth and adaptability in your business.

Understanding the Different Types of Milling Machines and Their Applications

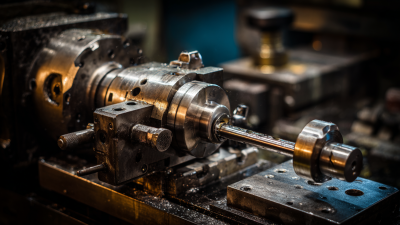

When selecting a milling machine for your business, it is essential to understand the various types available and their specific applications. Milling machines come in several forms, including vertical and horizontal machines, each designed for distinct tasks. Vertical milling machines are ideal for precision work and can handle intricate designs, making them suitable for prototyping and small parts manufacturing. On the other hand, horizontal milling machines excel in cutting larger pieces of material and are often utilized for mass production due to their efficiency.

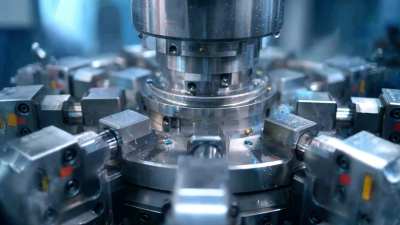

Additionally, CNC (Computer Numerical Control) milling machines have revolutionized the industry by offering automated processes that enhance accuracy and reduce labor costs. These machines are programmable, allowing operators to execute complex designs with ease, which is particularly beneficial for businesses that require repeatability in their production processes. Understanding the specific needs of your business and the characteristics of each type of milling machine can significantly impact productivity and overall operational success.

How to Choose the Right Milling Machine for Your Business Needs

| Type of Milling Machine | Application | Advantages | Considerations |

|---|---|---|---|

| Vertical Milling Machine | Used for drilling and machining small parts | Versatile, easy to use | Limited to lighter materials |

| Horizontal Milling Machine | Best for machining heavier materials | More efficient for thick materials | Requires more space |

| CNC Milling Machine | Automated machining for complex parts | High precision and automation | Higher initial investment |

| Turret Milling Machine | Flexible machining with adjustable heads | Versatile configurations | May require more operator skill |

Evaluating Your Business Needs: Production Volume and Component Complexity

When selecting a milling machine for your business, evaluating your specific production volume and the complexity of the components is essential. Different production volumes dictate how robust and efficient your machinery needs to be. For high-volume operations, a machine with a faster feed rate and greater durability is paramount. This ensures that you can meet demand without compromising on quality. In contrast, businesses with lower production requirements may focus on more versatile machines that offer flexibility for various tasks without the need for large-scale production capabilities.

Component complexity is another critical factor. If your business involves manufacturing intricate parts with tight tolerances, investing in advanced milling machines equipped with features like multi-axis capability and precision tooling becomes necessary. These machines can handle various geometries, allowing for the production of complex components with high accuracy. On the other hand, simpler components might not require such advanced machinery, enabling businesses to optimize their equipment choices based on specific needs, ultimately balancing cost and functionality.

The Role of Precision and Tolerance Specifications in Machine Selection

When selecting a milling machine for your business, understanding precision and tolerance specifications is crucial. Precision refers to the machine's ability to produce consistent and accurate results, while tolerance specifies the allowable variation in measurements during machining. These factors significantly impact the overall quality of the manufactured parts and the efficiency of your production process.

Tips: To ensure you choose a milling machine that meets your precision requirements, evaluate the specific tolerances required for your projects. Different industries often have varying standards. For example, aerospace components may require tighter tolerances compared to general metalworking. Consult the machine's specifications and seek models that offer the precision levels necessary for your applications.

Additionally, consider the type of materials you will be machining. Different materials can react uniquely to machining processes, influencing the required precision and tolerances. It’s advisable to run tests on samples with your prospective machine to assess real-world performance. By aligning your selection criteria with your business needs and product specifications, you can ensure optimal results from your milling operations.

Cost-Benefit Analysis: Initial Investment vs. Long-Term Operational Efficiency

When selecting a milling machine for your business, it's crucial to conduct a cost-benefit analysis that weighs the initial investment against long-term operational efficiency. The upfront costs of a milling machine, including its purchase price, installation, and training, can be substantial. However, understanding how these costs correlate with potential productivity gains and cost savings over time is essential for making a sound decision.

Long-term operational efficiency often hinges on the machine's reliability, maintenance needs, and production speed. A more expensive milling machine may provide advanced features, greater durability, and better precision, leading to lower operational costs and reduced downtime in the future. Conversely, choosing a less expensive model might seem advantageous initially, but if it results in frequent repairs or inefficiencies, the long-term costs could outweigh the savings. By carefully considering these factors, businesses can make informed decisions that align with their financial goals and operational needs.

Related Posts

-

The Future of Advanced Milling Machine Technologies

-

7 Best Tips for Choosing the Right Milling Machine Machine for Your Business

-

2025 Trends: Unlocking the Secrets of the Best Industrial Milling Machines for Maximum Efficiency

-

How to Choose the Best Industrial Milling Machine for Your Business Needs

-

China's Pinnacle of Excellence: The Unmatched Best Machine Repairing Machine for Global Buyers

-

Discover Innovative Alternatives to the Best Production Machine for Global Buyers