What is a Custom Machine and How Does It Work?

A Custom Machine is designed to meet specific needs. This specialized equipment can revolutionize the production process. Companies often seek custom machines to enhance efficiency.

Understanding how a Custom Machine works involves examining its components and functions. It typically includes unique features tailored to particular tasks. These machines are often more effective than standard models.

However, creating a Custom Machine can be challenging. It requires careful planning and design. Mistakes during this process can lead to increased costs and delays. It's essential to refine ideas and focus on clear objectives. Each step requires attention to detail for optimal results.

What is a Custom Machine?

A custom machine is tailored to meet specific needs in various industries. These machines are designed for unique processes or products. Industries often require equipment that standard machines cannot provide. A custom machine ensures efficiency and accuracy in production.

According to a report by MarketsandMarkets, the custom machinery market is projected to reach over $100 billion by 2025. Many companies invest heavily in these machines. They aim for higher productivity and adaptability. However, the initial costs can be quite high. Smaller businesses may hesitate to invest, fearing a lack of immediate returns. The challenge lies in striking a balance between innovation and financial viability.

Custom machines can address specific problems. For instance, they can optimize complicated assembly lines or improve quality control. However, their design process can be lengthy. Miscommunication between engineers and clients may lead to design flaws. Some machines may end up underperforming. Continuous feedback from users is critical for improvement. Industry reports emphasize the need for iterative design approaches to mitigate risks.

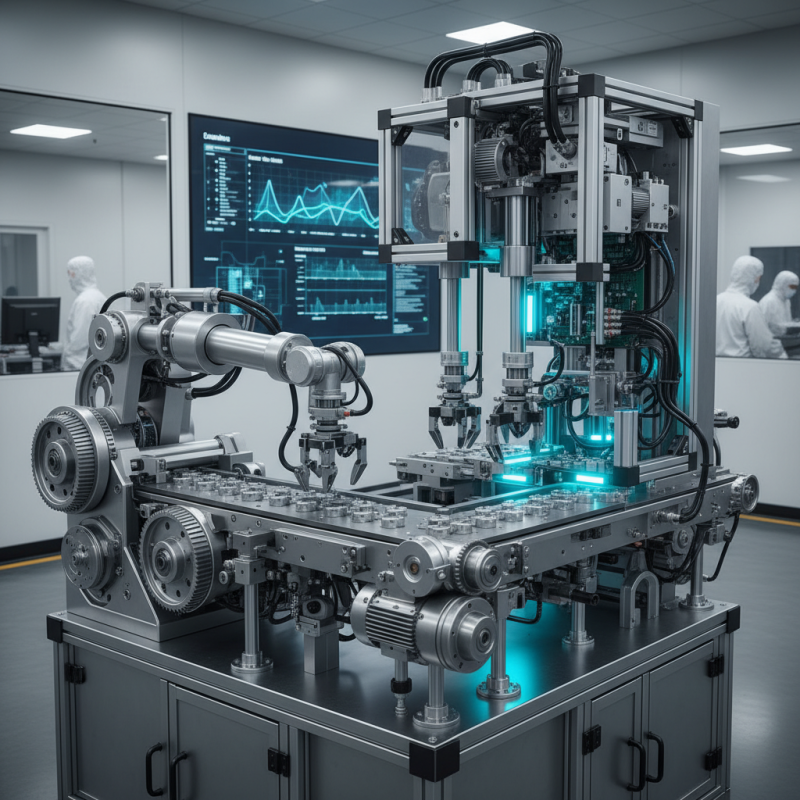

Key Components of Custom Machines

Custom machines are integral in various industries, designed to meet unique specifications. The core components of these machines include the framework, drive systems, and control systems. The framework provides structural support and stabilization. It's essential for performance and durability. Data shows that over 70% of machine failures can be traced back to inadequate support structures.

Drive systems are the heart of custom machines. They convert energy into mechanical motion. A failure in the drive system can halt production completely. Research indicates that optimizing these systems can improve efficiency by up to 25%. This highlights the need for careful design and implementation in machine operations.

Control systems govern the machine's operations. They ensure precision and functionality. However, the integration of advanced control systems often presents challenges. Training staff to effectively use these systems is crucial. Without proper understanding, the potential benefits may be lost. Inadequate training can lead to operational errors, impacting productivity. It’s a delicate balance between technology and human skill in manufacturing settings.

What is a Custom Machine and How Does It Work? - Key Components of Custom Machines

| Component | Description | Function | Materials Used | Applications |

|---|---|---|---|---|

| Frame | The main structure of the custom machine. | Provides support and stability. | Steel, Aluminum | Manufacturing, Robotics |

| Drive System | Mechanism that powers the machine. | Converts electrical energy into mechanical movement. | Motors, Gears | Automation, CNC Machines |

| Control System | User interface for managing operations. | Allows automation and control of functions. | Sensors, Controllers | Production Lines, Quality Control |

| Safety Features | Protective elements to ensure safe operation. | Prevents injury and machine damage. | Emergency Stops, Guards | Heavy Machinery, Construction |

| Power Supply | Source of energy for the machine. | Supplies electrical energy for operation. | Batteries, Generators | Remote Locations, Backup Systems |

The Process of Designing a Custom Machine

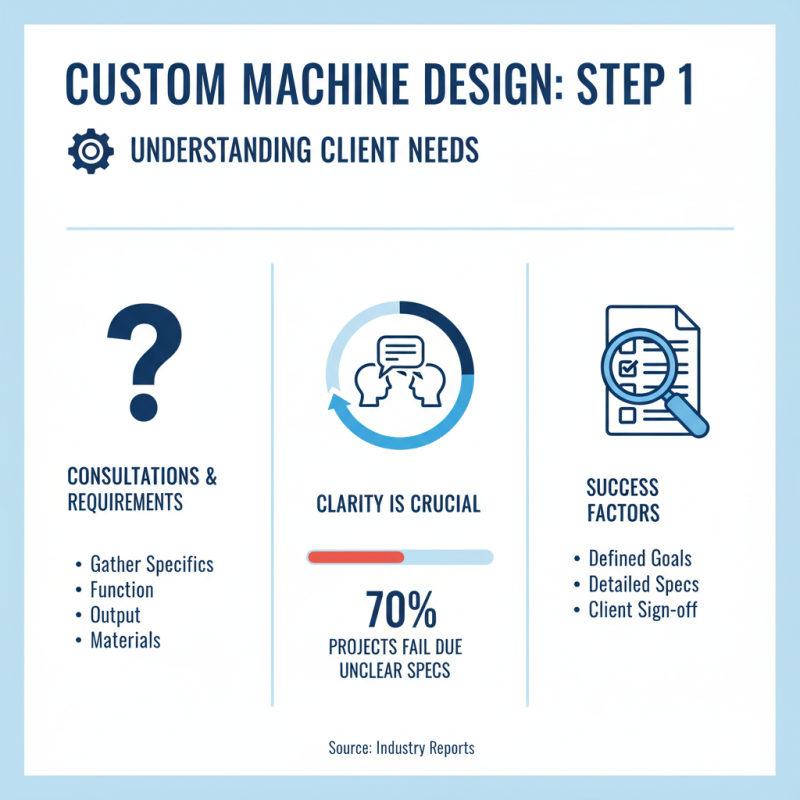

Designing a custom machine involves a systematic approach. The first step is understanding the client's needs. This may involve detailed consultations to gather specific requirements. According to industry reports, 70% of custom machine projects fail due to unclear specifications. Clarity is crucial.

Once the requirements are gathered, a concept design phase begins. Engineers draft initial designs using CAD software. Prototyping follows, allowing for real-world testing. Feedback from these tests is invaluable. It often leads to unexpected modifications. Up to 30% of designs face significant changes after prototype testing. This reflection phase is critical, often revealing technical flaws or discrepancies.

Finally, the manufacturing process comes into play. Precision in fabrication is vital. Advanced technologies like CNC machining can ensure this. However, even with high-tech tools, human error can lead to mistakes. Continuous process evaluation ensures better outcomes. Companies must be ready to adapt and refine their methods based on production challenges. Each iteration provides learning opportunities, driving improvements in future projects.

How Custom Machines Improve Efficiency and Productivity

Custom machines significantly enhance efficiency and productivity across various industries. According to a recent industry report, companies using tailored machinery have seen productivity improvements of up to 30%. This rise is attributed to automation and precision engineering, which reduce manual labor and minimize errors in production.

By integrating custom machines into workflows, businesses can optimize processes. For example, a customized assembly line can lead to faster production times. Reports indicate that companies experience a reduction in cycle times by as much as 25% with the right machine. These machines adapt to specific tasks, streamlining operations and cutting down on waste.

However, implementing custom machines is not without challenges. The initial investment can be high, which concerns many businesses. Organizations must conduct thorough cost-benefit analyses before proceeding. Furthermore, not every workflow benefits equally from custom solutions. Some industries might struggle to justify the shift, leading to a careful examination of machinery effectiveness.

Applications of Custom Machines in Various Industries

Custom machines are transforming many industries through automation and efficiency. In manufacturing, custom machines optimize production lines. They reduce waste while increasing output. A report from a leading industry analyst indicates that tailored machinery can improve efficiency by 30% in some sectors. This is significant in a competitive market.

The healthcare industry also benefits from custom machines. For instance, specialized equipment is essential for precise diagnostics. According to the HealthTech Journal, custom medical devices can reduce operational errors by up to 25%. However, developing these machines poses challenges. Designers must balance innovation with compliance and safety regulations.

In agriculture, custom machinery enhances productivity. Precision farming equipment allows for more accurate planting and crop management. A study by AgriTech Insights reveals that such machines can boost yields by 15% on average. Yet, integrating new technology may require a learning curve for workers. Some may resist change, leading to initial setbacks. These reflections show that while custom machines offer great potential, their implementation is not always straightforward.

Related Posts

-

5 Essential Tips for Maximizing Efficiency with Custom Machines in Manufacturing

-

Understanding the Advantages of the Best Custom Machine for Global Buyers

-

7 Compelling Reasons to Choose the Best Custom Machine for Your Business

-

Unlocking the Best Production Machine Technical Specifications and How to Maximize Efficiency

-

Top 5 Essential Parts Of Industrial Machines You Should Know About

-

Transforming Industries with Best Plastic Material Machine Practical Applications and How to Implement Them