Top 10 Essential Tips for Machine Repairing Machines?

In the realm of machine repair, understanding the intricacies of a Machine Repairing Machine is crucial. Experts like John Smith, a leading technician in this industry, emphasize, "Proper maintenance can extend a machine's lifespan significantly." This statement holds true for both novice and experienced repair specialists.

Machine Repairing Machines are complex tools. They require precise handling and a keen understanding of mechanics. Many overlook simple repairs, leading to larger issues. It is essential to equip oneself with the right knowledge and effective strategies. For instance, knowing the right lubricant can make all the difference in reducing wear and tear.

Despite technological advances, many still struggle with basic repairs. Some rush through tasks, making mistakes. This can result in costly damages. Reflecting on previous experiences shows that patience and thoroughness pay off. Each repair offers an opportunity to learn and improve.

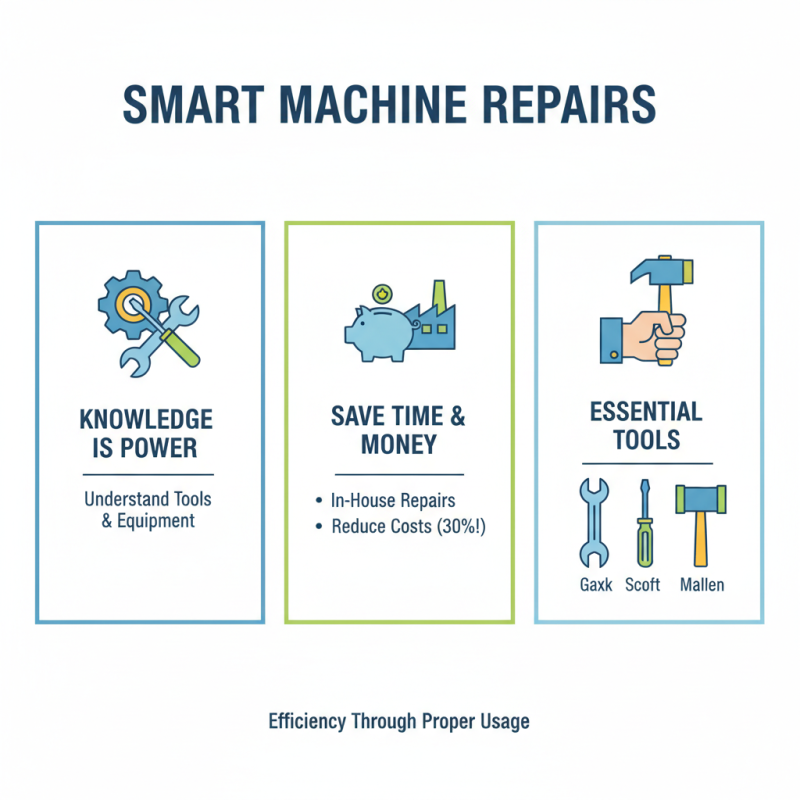

Understanding the Basics of Machine Repair Tools and Equipment

When it comes to machine repairs, understanding the tools and equipment is crucial. Many repairs can be done in-house, saving time and money. Reports show that improper tool usage increases repair costs by about 30%. Familiarizing yourself with basic tools such as wrenches, screwdrivers, and mallets can make repairs more efficient.

Tip: Always use the right tool for the job. Using the wrong tool can damage both the machine and the tool itself. It's a common mistake that can lead to frustrating delays.

Another important aspect is safety equipment. Wearing gloves and goggles is vital. A report by the National Safety Council indicates that over 50,000 injuries occur each year due to improper safety practices in machine repair. This highlights the need for a cautious approach when dealing with machines.

Tip: Regularly inspect your tools. Dull blades can lead to accidents and inefficiency. Taking time to maintain tools can prevent future problems and keep repair tasks manageable. Making small adjustments can lead to significant improvements in performance.

Identifying Common Machine Issues and Their Solutions

Identifying common machine issues is vital for effective repairs. According to a recent industry report, nearly 30% of machinery failures occur due to lack of maintenance. Regular checks can prevent costly breakdowns and downtime. Operators should look for unusual noises, vibrations, or leaks as early warning signs of trouble.

Another significant issue is electrical failures. The report indicates that 40% of machinery defects stem from electrical components. Inspecting wiring and connections can help catch these problems early. Operators often overlook these details. They assume everything is fine until it isn’t. This mindset can lead to severe consequences. Regular inspections can mitigate this risk significantly.

Additionally, wear and tear on parts is a common concern. According to statistics, almost 25% of machinery performance issues relate to worn-out components. Replacing parts proactively can enhance efficiency and prolong the lifespan of the equipment. However, many companies hesitate to invest in replacements until it's too late. As a result, they face higher repair costs and operational interruptions. Being aware of these issues is the first step toward ensuring machine longevity and efficiency.

Step-by-Step Guide to Diagnosing Machine Problems

Diagnosing machine problems can be tricky. A systematic approach is key. Start with the basics. Check for signs of wear and tear. Look for unusual noises or vibrations. These can indicate deeper issues.

Tip 1: Maintain a log of machine performance. This helps in identifying patterns over time. Is there a recurring problem? Keeping track can guide you.

Inspect electrical connections, too. Damaged wiring can lead to failures. Ensure all components are securely fastened. Loose connections can cause malfunctions.

Tip 2: Don't ignore small signs. A minor issue can escalate quickly. Address it as soon as you notice anything odd. Sometimes, it’s easy to overlook these. Yet, a little caution goes a long way.

Always remember to prioritize safety. Disconnect power before doing any checks. It’s a simple step that prevents accidents. Reflect on your practices often. Are you being thorough? Revisiting your methods can enhance your skills.

Top 10 Essential Tips for Machine Repairing Machines

| Tip Number | Tip Description | Benefits | Tools Required |

|---|---|---|---|

| 1 | Always read the user manual before starting repair. | Understanding machine's specifications and troubleshooting sections. | User manual |

| 2 | Turn off power before conducting repairs. | Prevents electrical shock and injury. | Safety gloves, multimeter |

| 3 | Note down symptoms carefully. | Helps in accurately diagnosing issues. | Notebook, pen |

| 4 | Use the right tools for the job. | Increases repair efficiency and safety. | Screwdrivers, wrenches, pliers |

| 5 | Check for loose connections. | Often a simple fix for many issues. | Screwdrivers, inspection tools |

| 6 | Look for signs of wear and tear. | Helps in preventive maintenance. | Inspection mirror, flashlight |

| 7 | Keep your workspace organized. | Improves focus and safety during repairs. | Workbench, trays |

| 8 | Test your repair before final assembly. | Ensures the issue is resolved. | Various testing equipment |

| 9 | Document your repairs and findings. | Useful for future reference and troubleshooting. | Notebook, digital camera |

| 10 | Seek professional help when necessary. | Prevents further damage and loss. | N/A |

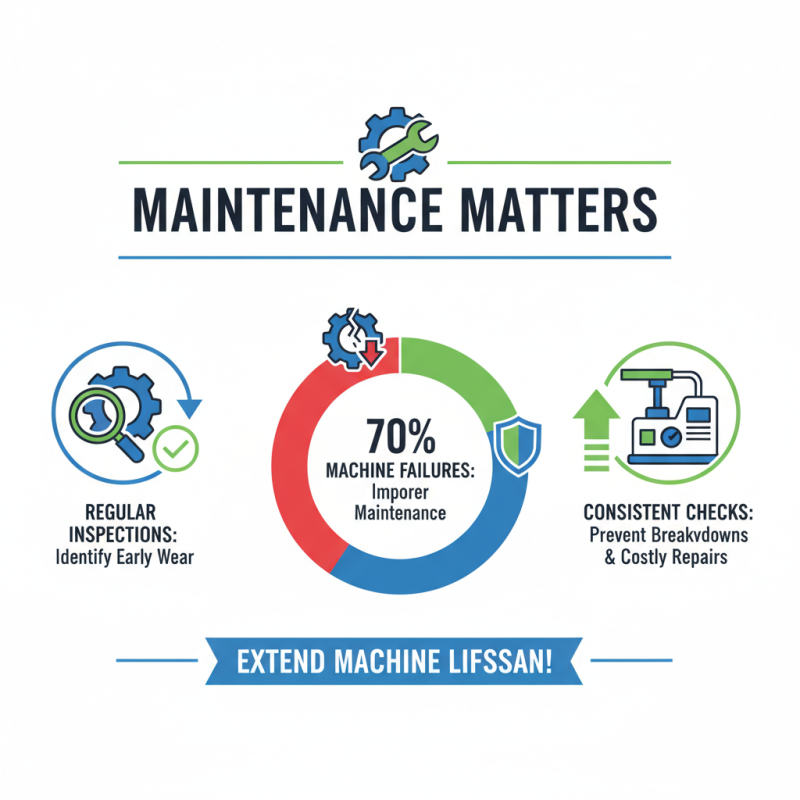

Effective Maintenance Techniques for Longevity of Machines

Effective maintenance is crucial for extending the lifespan of machines. Regular inspections can identify wear and tear early. A study shows that 70% of machine failures stem from improper maintenance. Consistent checks help prevent breakdowns and costly repairs.

Lubrication plays a key role in machine upkeep. Without adequate lubrication, components can wear out quickly. Data indicates that machines run 30% longer with proper lubrication schedules. Dust and debris also impact machine efficiency. Having a dedicated cleaning routine enhances performance significantly.

Operators should be trained to recognize issues early. Ignoring small faults can lead to major malfunctions. In fact, 40% of repairs are a result of unaddressed minor issues. Keeping a detailed maintenance log helps track machine performance. This log highlights patterns and aids in troubleshooting. Consider scheduling maintenance during off-peak hours. This minimizes disruptions and promotes safety. Reflecting on maintenance processes can reveal improvement areas.

Safety Precautions to Follow While Repairing Machines

When repairing machines, safety must be a priority. According to the U.S. Bureau of Labor Statistics, over 400,000 workplace injuries occur annually in manufacturing. This stark statistic emphasizes the need for proper safety precautions. Always wear personal protective equipment (PPE) like gloves, goggles, and steel-toed boots. These items can greatly reduce the risk of injury. A recent industry report noted that using PPE reduces incident rates by 24%.

Proper machine isolation is essential. Before beginning repairs, ensure that power sources are disconnected. This prevents unexpected machine startup, which can lead to serious injuries. Operators should use lockout/tagout (LOTO) procedures. Many companies report that implementing LOTO can decrease injury rates significantly. A common oversight is neglecting to communicate with team members about ongoing repairs. Clear communication can avert accidents.

Be mindful of the workspace. A cluttered area can increase the risk of trips and falls. Organize tools and materials effectively. Periodic inspections of work sites are necessary. They help identify hazards that may have gone unnoticed. Lastly, training on emergency procedures cannot be overlooked. Workers should know what actions to take in case of an accident. Neglecting safety measures can lead to dangerous outcomes.

Related Posts

-

Revolutionizing Industrial Standards at the 138th Canton Fair 2025 with Advanced Machine Repairing Machines

-

Top 10 Tips for Effective Machine Repairing Machine Techniques

-

Essential Tips for Choosing Metal Parts Machine Solutions?

-

5 Essential Tips to Choose the Best Commercial Machine for Your Business Growth

-

Why Choose a Machine Welding Machine for Your Industrial Needs

-

Elevating Industry Standards with the Best Service Machine for Global Buyers