Exploring Innovative Alternatives to the Best Industrial Packing Machine

In today's rapidly evolving manufacturing landscape, the efficiency and reliability of an Industrial Packing Machine play a critical role in the overall productivity of a business. As companies strive to optimize their packing processes, they are increasingly seeking innovative alternatives that can deliver greater flexibility, cost-effectiveness, and sustainability. This ultimate guide will explore various cutting-edge technologies and solutions that serve as viable substitutes for traditional packing machines. From automated systems that enhance throughput to eco-friendly packaging advancements that cater to modern consumer demands, we will delve into the myriad of options available in the market. By examining these innovative alternatives, businesses can make informed decisions that not only elevate their packing operations but also contribute to a more sustainable future. Join us as we navigate through the exciting possibilities that await in the realm of industrial packing solutions.

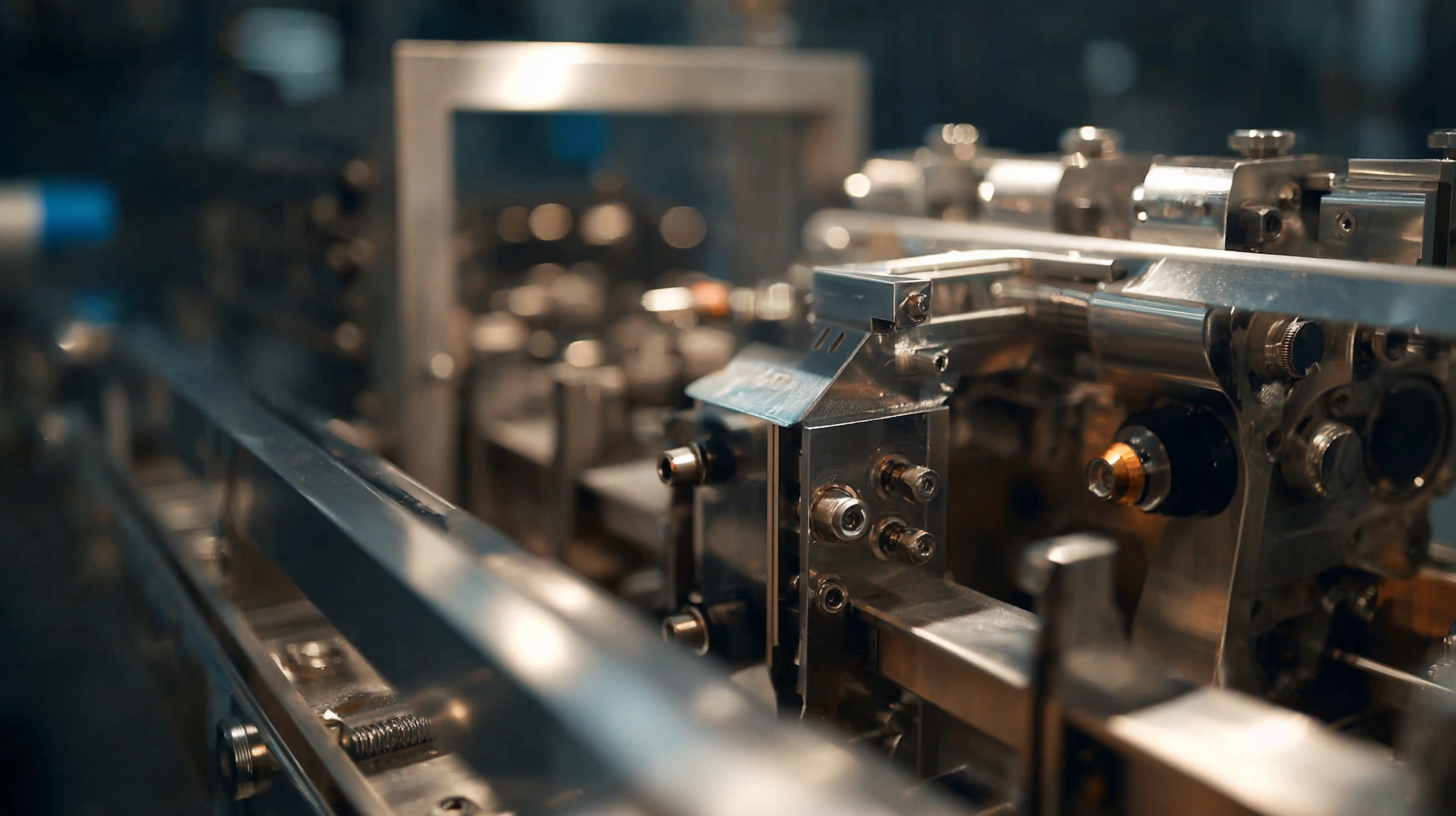

Innovative Features of the Latest Industrial Packing Machines

In the ever-evolving landscape of industrial packaging, the latest machines are showcasing a remarkable array of innovative features that enhance efficiency and adaptability. According to a report by Research and Markets, the global industrial packaging market is projected to reach USD 250 billion by 2027, driven by advancements in technology and automation. Modern machines now incorporate smart sensors and IoT capabilities, which allow for real-time monitoring and data analytics. This enables manufacturers to optimize production lines, reduce waste, and increase throughput, meeting the growing demands of e-commerce and global trade.

Additionally, the advent of sustainable packaging solutions has led to the integration of eco-friendly materials and practices within these machines. A study from Smithers indicates that sustainable packaging is expected to grow at a CAGR of 5.1% over the next five years, as companies strive to meet consumer demand for greener options. The latest industrial packing machines not only adapt to various packaging formats—such as biodegradable films and recycled materials—but also feature energy-efficient designs that minimize their environmental impact. These innovations signify a transformative shift in the industrial packing sector, aligning productivity with sustainability.

Sustainable Materials in Industrial Packaging Solutions

Sustainability is becoming a cornerstone in the industrial packaging sector, with companies increasingly seeking innovative materials that minimize environmental impact. According to a recent report by MarketsandMarkets, the global sustainable packaging market is projected to reach $532 billion by 2027, growing at a CAGR of 9.7%. With the rising demand for more eco-friendly solutions, manufacturers are exploring alternatives such as biodegradable polymers, recycled content, and renewable materials. These innovations not only help reduce waste but also improve the overall efficiency of packaging processes.

Sustainability is becoming a cornerstone in the industrial packaging sector, with companies increasingly seeking innovative materials that minimize environmental impact. According to a recent report by MarketsandMarkets, the global sustainable packaging market is projected to reach $532 billion by 2027, growing at a CAGR of 9.7%. With the rising demand for more eco-friendly solutions, manufacturers are exploring alternatives such as biodegradable polymers, recycled content, and renewable materials. These innovations not only help reduce waste but also improve the overall efficiency of packaging processes.

When considering sustainable materials, businesses should focus on lifecycle assessments to evaluate the environmental impact from production to disposal. One effective tip is to incorporate bioplastics made from renewable resources, which can significantly lower carbon footprints compared to conventional plastics. Additionally, exploring the potential of reusable and collapsible packaging solutions can further contribute to sustainability efforts without compromising efficiency.

Moreover, opting for paper-based packaging materials can be a game-changer, especially with textiles such as mushroom mycelium and seaweed gaining traction. These materials are not only biodegradable but also offer robust protection for goods. Companies should also keep an eye on innovative barrier coatings that enhance the durability of paper while maintaining environmental responsibility. By integrating these innovative alternatives, businesses can lead the charge toward a greener future in industrial packaging.

How Chinese Manufacturing Redefines Quality Standards in Packing

Chinese manufacturing has long been a global powerhouse, but its recent advancements in packing technology showcase a new epoch in redefining quality standards. With a focus on innovation and efficiency, Chinese manufacturers are not only enhancing traditional packing methods but also introducing state-of-the-art machinery that elevates industry standards worldwide. These innovations include automation, smart technology, and sustainable practices that provide both reliability and enhanced performance.

One of the most significant shifts in the packing industry is the incorporation of intelligent systems, such as AI-driven packing machines and IoT-enabled tracking solutions. These technologies streamline operations, reduce waste, and improve accuracy, offering manufacturers greater control over their processes. Additionally, the commitment to sustainability has led to the development of eco-friendly packing materials and methods that not only meet international standards but also appeal to the increasing consumer demand for green solutions. As Chinese manufacturing continues to evolve, its approach to packing sets a benchmark that others in the industry aspire to achieve.

The Role of Automation in Enhancing Packing Efficiency

Automation is increasingly recognized as a pivotal factor in enhancing packing efficiency, particularly within the food and beverage sector. Despite its slower adoption in these industries, automation is being heralded as a solution to complex processing challenges. The global packaging automation market is projected to grow significantly, anticipated to reach USD 136.47 billion by 2032. This surge underscores the necessity for businesses to embrace technological advancements to streamline operations and reduce costs.

Implementing automation not only improves productivity but also reshapes roles throughout the packaging supply chain. Automated solutions are essential for e-commerce, where the rapid growth of online shopping demands faster and more efficient packaging processes. By utilizing advanced technologies, companies can optimize their operations and respond effectively to increased consumer demand.

**Tips:**

1. Assess your current packing process to identify areas where automation could deliver the most benefit.

2. Invest in training for your team to ensure they can effectively utilize new automated systems, maximizing potential gains in efficiency and productivity.

Case Studies: Success Stories of Innovative Packing Techniques in Industry

In recent years, the packaging industry has witnessed a surge in innovative techniques that enhance efficiency and sustainability. Case studies reveal that companies adopting these methods have not only improved operational efficiency but also significantly reduced waste. For instance, a report by Smithers Pira indicates that the use of automated packing solutions can boost productivity by up to 30%, enabling firms to meet increasing consumer demands without compromising on quality.

One notable success story comes from a leading consumer goods manufacturer that implemented a novel packing technique involving biodegradable materials. This initiative resulted in a 40% reduction in plastic waste, aligning with global sustainability goals. Similarly, a recent study from the Packaging Machinery Manufacturers Institute (PMMI) highlights that integrating IoT technology into industrial packing machines has led to enhanced monitoring and control, resulting in a 25% decrease in downtime during production. These innovative approaches not only cater to the evolving market but also demonstrate a commitment to environmentally responsible practices, setting a new standard in the industry.