5 Essential Tips for Maximizing Efficiency with Custom Machines in Manufacturing

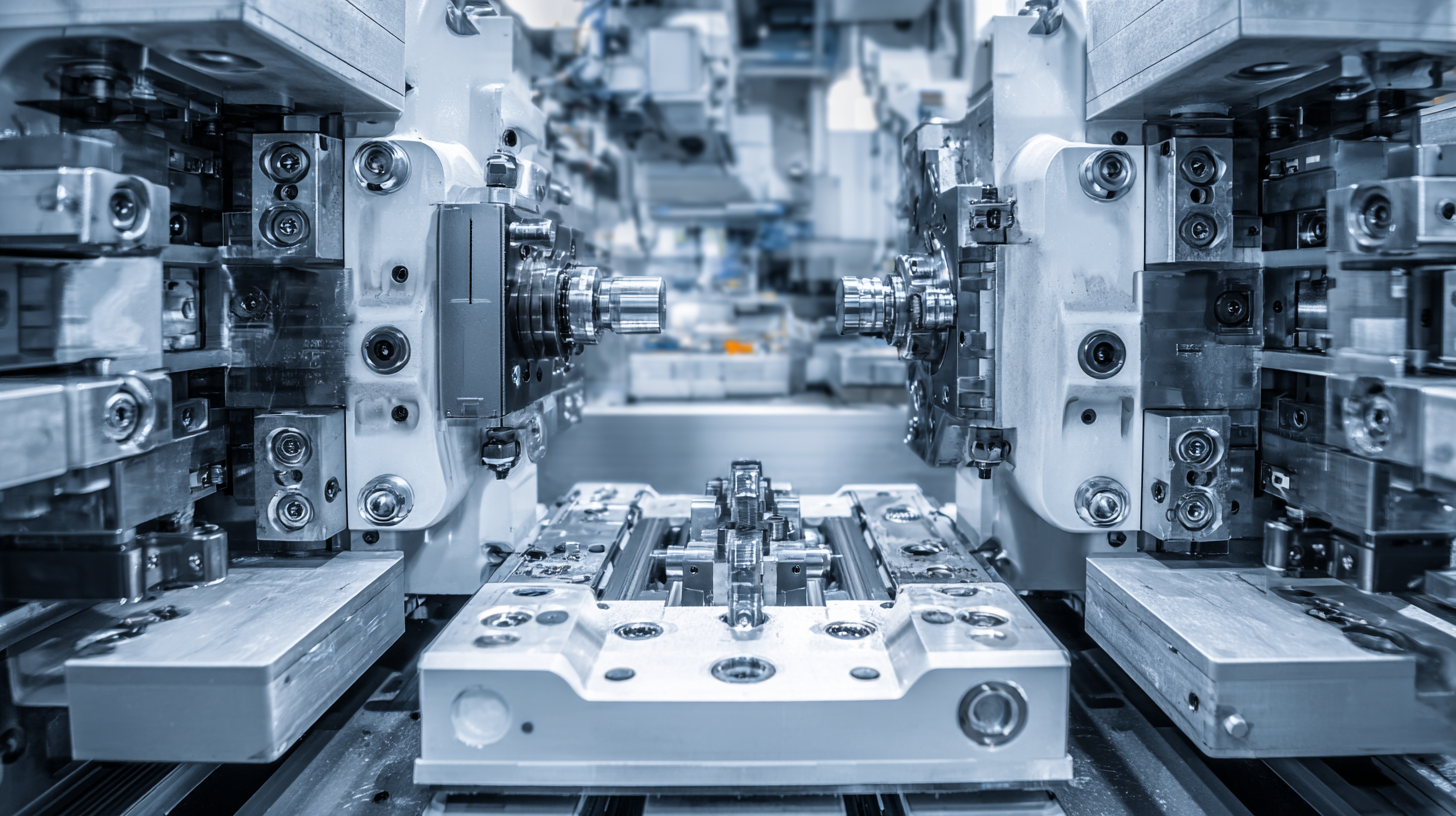

In today's highly competitive manufacturing landscape, leveraging advanced technology is essential for maximizing efficiency and productivity. According to a report by the International Federation of Robotics, the global market for automation solutions, including custom machines, is expected to reach $250 billion by 2025, highlighting the increasing reliance on customized production systems. Custom machines provide tailored solutions that optimize workflows, reduce waste, and enhance precision, enabling manufacturers to adapt swiftly to changing demands. As industries strive for operational excellence, implementing effective strategies for utilizing custom machines is crucial. In this blog, we delve into five essential tips that can help manufacturers unlock the full potential of custom machinery, driving better performance and ensuring sustainable growth in a rapidly evolving market.

Understanding Your Manufacturing Needs for Custom Machines

When considering custom machines for manufacturing, the first step is understanding your specific manufacturing needs. This involves analyzing your production processes, identifying bottlenecks, and determining which tasks could benefit from automation. By clearly defining your objectives, you can tailor custom machines to enhance your operational efficiency.

When considering custom machines for manufacturing, the first step is understanding your specific manufacturing needs. This involves analyzing your production processes, identifying bottlenecks, and determining which tasks could benefit from automation. By clearly defining your objectives, you can tailor custom machines to enhance your operational efficiency.

One essential tip for maximizing efficiency is to leverage data-driven insights. With the increasing role of AI and automation in manufacturing, data plays a crucial role in optimizing machine performance. Implementing systems that collect and analyze production data allows you to make informed decisions about modifications and upgrades to your custom machines, ultimately leading to reduced downtime and improved productivity.

Additionally, embracing the concept of lights-out manufacturing can significantly impact your operations. By integrating custom machines that operate autonomously with minimal human intervention, you not only maximize efficiency but also minimize labor costs. This future-forward approach ensures that your manufacturing processes remain competitive and innovative in an ever-evolving industry landscape.

Incorporating Automation for Enhanced Performance

In today's manufacturing landscape, automation stands out as a critical driver for efficiency. Incorporating automation not only streamlines processes but fundamentally transforms how operations are managed. For instance, Industry 4.0 technologies, such as the Industrial Internet of Things (IoT) and artificial intelligence (AI), enable real-time monitoring and data analysis. This integration allows manufacturers to identify bottlenecks and optimize production line operations dynamically. As sensors and automated systems communicate seamlessly, the manufacturing environment becomes more adaptive, leading to enhanced performance and reduced downtime.

Moreover, the advancement of automation technologies contributes to greater sustainability in manufacturing. By leveraging AI and automation, companies can improve resource allocation, minimize waste, and enhance energy efficiency. The ability to forecast demands and automate supply chain processes leads not only to cost savings but also fosters a responsible approach to production. As the industry shifts towards a more digitized and environmentally conscious future, the adoption of automated solutions will be paramount for manufacturers aiming to stay competitive while achieving substantial sustainability goals.

Regular Maintenance Strategies to Minimize Downtime

Regular maintenance is crucial in maximizing efficiency with custom machines in manufacturing. Establishing a proactive maintenance schedule can significantly reduce unexpected downtimes. This involves routine inspections, recalibrating machinery, and replacing worn-out parts before they fail. By staying ahead of potential issues, manufacturers can ensure that their custom machines run smoothly and consistently, leading to increased productivity and reduced costs associated with emergency repairs.

Moreover, leveraging technology can enhance maintenance efforts. Implementing monitoring systems that track equipment performance can provide valuable insights and alert managers to potential failures before they occur. Utilizing predictive maintenance analytics allows organizations to optimize their schedules and focus on high-priority tasks, ensuring that the manufacturing process remains uninterrupted. By combining these strategies with regular maintenance routines, companies can create a resilient manufacturing environment that maximizes uptime and efficiency.

Utilizing Data Analytics for Continuous Improvement

In today's competitive manufacturing landscape, leveraging data analytics has emerged as a critical strategy for continuous improvement. According to a report by McKinsey, companies that utilize data-driven decision-making in their manufacturing processes can boost productivity by up to 20%. This significant increase underscores the importance of harnessing data analytics to optimize operations and enhance efficiency. By collecting and analyzing data from custom machines, manufacturers can identify bottlenecks, monitor machine performance, and predict maintenance needs, ultimately minimizing downtime.

Moreover, Industry 4.0 has ushered in a new era of smart manufacturing, where connected devices generate vast amounts of data. A study by Deloitte suggests that organizations employing advanced analytics can achieve an estimated 15% reduction in production costs. By implementing real-time analytics, manufacturers can make informed decisions that lead to more streamlined operations. Integrating analytics into manufacturing workflows enables a proactive approach, allowing teams to adapt quickly to changing conditions and customer demands, thus enhancing overall efficiency and driving continuous improvement.

Maximizing Efficiency with Custom Machines in Manufacturing

Effective Training Programs for Operating Custom Machinery

In the realm of custom machinery, having an effective training program is essential for ensuring operators maximize their efficiency. A well-structured training program not only enhances skill levels but also promotes safety and consistency in manufacturing processes. To achieve these goals, it's important to incorporate hands-on training sessions alongside theoretical lessons. By doing so, operators can gain practical experience and immediately apply what they've learned, leading to improved operational performance.

Furthermore, regular assessments and feedback are crucial components of any training program. Conducting periodic evaluations allows businesses to identify skill gaps and tailor training sessions accordingly. This proactive approach helps maintain high standards and keeps operators engaged in continuous learning. Another tip is to encourage collaboration among team members during training, fostering an environment of shared knowledge and support. This teamwork can lead to innovative solutions and increased efficiency when operating custom machinery.

By focusing on these essential aspects of training, manufacturers can cultivate a workforce that is not only proficient in operating custom machines but also committed to ongoing improvement and productivity.

5 Essential Tips for Maximizing Efficiency with Custom Machines in Manufacturing - Effective Training Programs for Operating Custom Machinery

| Tip Number | Tip Description | Training Method | Expected Outcome |

|---|---|---|---|

| 1 | Implement Structured Onboarding Programs | Interactive Workshops | Faster ramp-up for new operators |

| 2 | Utilize Simulation-Based Training | Virtual Reality | Reduced error rates and increased confidence |

| 3 | Encourage Continuous Learning | Weekly Skill Development Sessions | Higher adaptability to new technologies |

| 4 | Implement Visual Management Tools | On-the-Job Training with Visual Aids | Improved machine operation understanding |

| 5 | Foster a Feedback Culture | Regular Team Meetings | Enhanced team collaboration and efficiency |

Related Posts

-

Understanding the Advantages of the Best Custom Machine for Global Buyers

-

7 Compelling Reasons to Choose the Best Custom Machine for Your Business

-

Unlocking the Best Production Machine Technical Specifications and How to Maximize Efficiency

-

Exploring the Versatility and Applications of the Best Service Machine in Diverse Industries

-

Discover Innovative Alternatives to the Best Production Machine for Global Buyers

-

5 Essential Tips to Choose the Best Commercial Machine for Your Business Growth