Essential Tips for Choosing Metal Parts Machine Solutions?

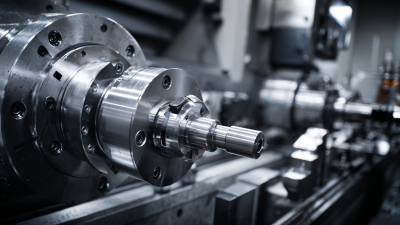

When selecting a "Metal Parts Machine" solution, decisions matter. Industry expert John Smith once said, “Choosing the right machine shapes your future.” His insight resonates in today's competitive landscape. The growing demand for precision and efficiency drives innovation in metal parts production.

Navigating this realm can be daunting. Many factors play a role, from materials to technology. You might grapple with the latest advancements versus time-tested methods. Each choice influences not just output, but quality and durability too. It’s crucial to align machine capabilities with production needs.

Competition is fierce, and not everyone succeeds. Reflection on past decisions can reveal valuable lessons. You might find that the most costly machines aren’t always the best fit. Understanding your requirements deeply can pave the way for smarter investments in "Metal Parts Machine" solutions.

Understanding the Importance of Metal Parts in Machinery Solutions

Metal parts play a crucial role in the functionality of machinery solutions. According to a report from the International Federation of Robotics, around 80% of manufacturers rely on metal components for their machines. These parts ensure durability and efficiency in operations across various industries. Whether in automotive, aerospace, or electronics, metal components often dictate performance.

Precision is vital when selecting metal parts. A minor flaw can lead to significant operational inefficiencies. For instance, a study by the American Society of Mechanical Engineers highlights that 30% of machine failures are due to inadequate metal part quality. This underscores the need for thorough inspections and testing before implementation. Today, manufacturers are encouraged to use advanced technologies for better quality assurance.

Choosing the right material is equally important. Steel, aluminum, and titanium offer distinct benefits. Steel is favored for strength, while aluminum is known for its lightweight properties. Yet, some may overlook the processing complexities. Not all parts can be machined easily from every metal. It’s essential to understand the specific requirements of each machinery solution. This knowledge can lead to better decision-making and reduced costs.

Essential Tips for Choosing Metal Parts Machine Solutions

This bar chart illustrates the popularity of different metal types used in machinery solutions. Aluminum and steel are the most preferred materials, highlighting their importance in various applications.

Identifying Your Manufacturing Needs and Specifications

When selecting metal parts machine solutions, it's crucial to pinpoint your specific manufacturing needs. Various industries have different requirements. For instance, the aerospace industry often demands high precision and lightweight materials. In contrast, the automotive sector may prioritize cost-effectiveness and durability. Research indicates that 65% of manufacturers struggle with meeting such diverse needs due to inadequate understanding of their specifications.

It’s vital to conduct a thorough analysis of the desired material properties. This includes tensile strength, corrosion resistance, and thermal stability. Data shows that 75% of product failures stem from poor material selection. Small adjustments can lead to significant performance changes. Narrowing down these specifications guides manufacturers toward the right machine options.

Every choice has its trade-offs. For example, opting for a more expensive machine may yield higher quality parts. On the other hand, lower-cost solutions might cut corners. The key is to balance budget constraints with the ultimate quality required. Reflecting on past projects can help identify potential pitfalls. Each decision should align closely with your company’s long-term goals.

Evaluating Different Types of Metal Materials for Durability

When selecting metal parts for machinery, evaluating the right material is crucial. Various metals offer unique advantages in durability, strength, and resistance to environmental factors. For example, steel is known for its tensile strength, making it ideal for heavy-duty applications. Aluminum is lightweight and corrosion-resistant, suitable for applications requiring reduced weight.

According to industry reports, stainless steel accounts for around 70% of the metal parts market due to its resistance to rust and wear. It performs well in harsh environments, ensuring longevity. Meanwhile, titanium is emerging as a favorite due to its high strength-to-weight ratio. However, it is also significantly more expensive, which can lead to budgeting challenges.

Tip: Always assess the specific requirements of your application. Consider loads, temperatures, and environmental exposure when selecting a material. Additionally, consult with engineers to understand current standards and practices. Another tip: analyze lifecycle costs. Sometimes, cheaper materials might lead to increased maintenance and replacements over time. Reflecting on these factors can guide you to the optimal choice, balancing performance with cost.

Essential Tips for Choosing Metal Parts Machine Solutions - Evaluating Different Types of Metal Materials for Durability

| Metal Type | Durability Rating | Corrosion Resistance | Weight | Cost per kg |

|---|---|---|---|---|

| Aluminum | High | Good | Lightweight | $2.50 |

| Stainless Steel | Very High | Excellent | Moderate | $3.00 |

| Carbon Steel | Medium | Poor | Heavy | $1.20 |

| Titanium | Very High | Good | Lightweight | $15.00 |

| Bronze | High | Good | Moderate | $5.00 |

Comparing Manufacturing Processes for Efficiency and Cost-effectiveness

When selecting metal parts machine solutions, it's vital to compare manufacturing processes. Efficiency often hinges on the techniques used. Different processes like CNC machining and additive manufacturing serve unique needs. CNC machining is precise but can be time-consuming. Additive manufacturing offers speed, yet it may lack certain mechanical properties.

Cost-effectiveness is another critical factor. Traditional methods might have lower initial costs but can incur higher operational expenses. Meanwhile, newer technologies may require significant investment upfront but lead to savings in the long run. Companies must weigh these trade-offs carefully. Sometimes, sticking to familiar processes feels safer, even if innovation could yield better results.

Reflecting on past choices is also important. Have previous decisions led to waste? Are there areas for improvement? Analyzing these aspects can guide better solutions. The balance between efficiency and cost is delicate and requires constant evaluation.

Selecting Reliable Suppliers and Establishing Quality Standards

Choosing a reliable supplier for metal parts is crucial. Look for vendors with a proven track record. Examine their experience in the industry. Ask for references and case studies. Suppliers should share information on their production processes. This transparency builds trust.

Establishing quality standards is equally important. Define specific benchmarks for the materials and parts you need. Quality inspections should be part of your agreement. Don’t skip the testing phase, even if it seems redundant. Consider implementing routine audits. This can reveal any issues before they escalate.

Pay attention to communication as well. Regular updates can prevent misunderstandings. Some suppliers may not respond timely, leading to delays. Be cautious and negotiate clear terms. A balance between cost and quality is essential. Reflect often on your choices. What works today might not suit future needs.

Related Posts

-

How to Optimize Production Efficiency for Metal Parts Machine

-

How to Choose the Best Metal Parts Machine for Your Manufacturing Needs

-

Unlocking the Advantages of Metal Parts Machine in Modern Manufacturing

-

Elevate Your Operations with the Best Welding Machines Made in China for Global Markets

-

10 Essential Tips for Sourcing the Best Service Machine for Your Business

-

Unique Challenges with the Best Machine Repairing Machine