Exploring the Top Examples of Best Parts For Machine Upgrades

In today's rapidly evolving industrial landscape, the demand for efficient and high-performing machinery is paramount. According to a report by McKinsey, the global industrial machinery market is projected to reach $800 billion by 2025, driven by trends in automation and smart manufacturing. Upgrading machinery is a key strategy for businesses aiming to enhance productivity and maintain competitiveness.

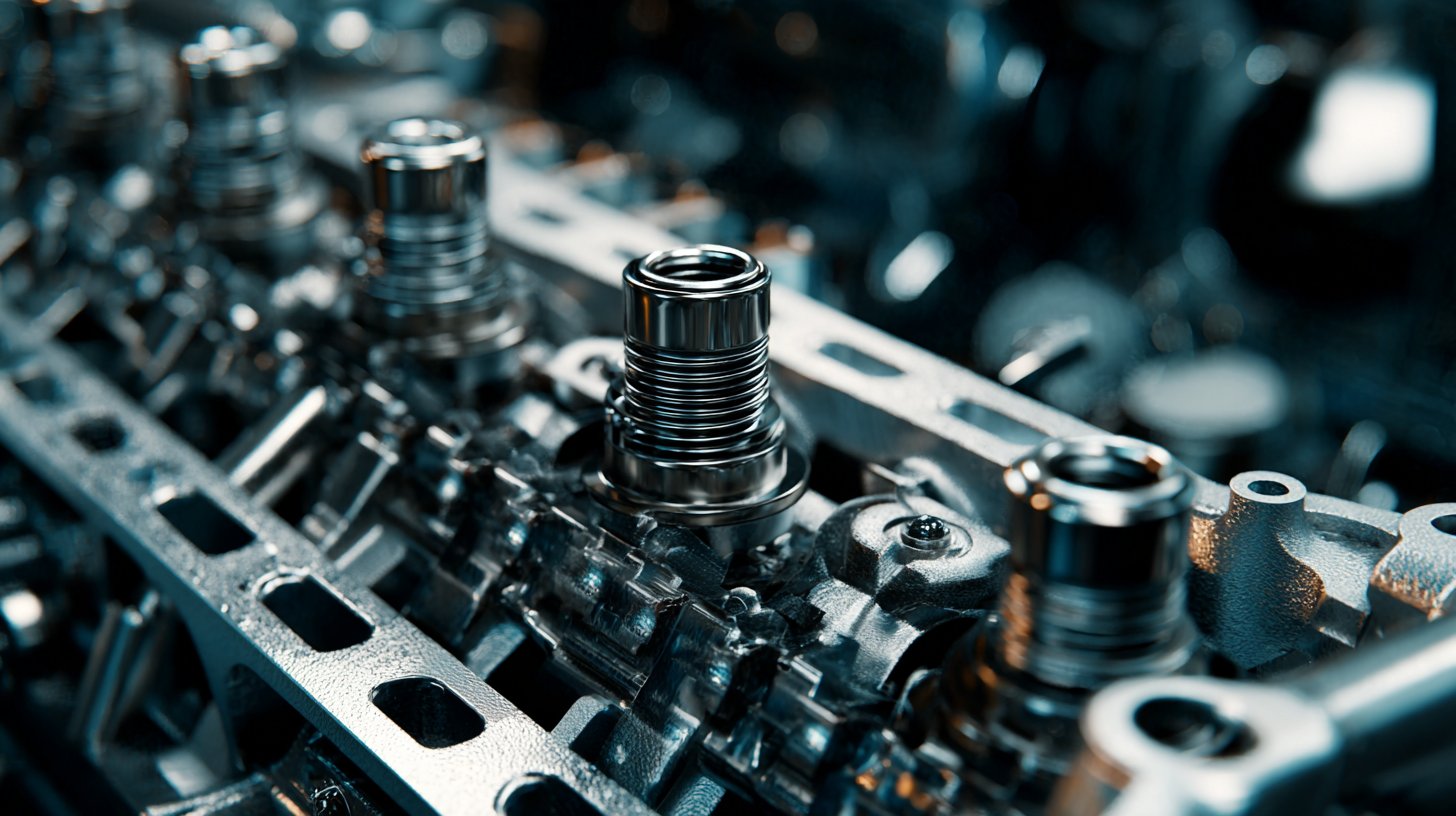

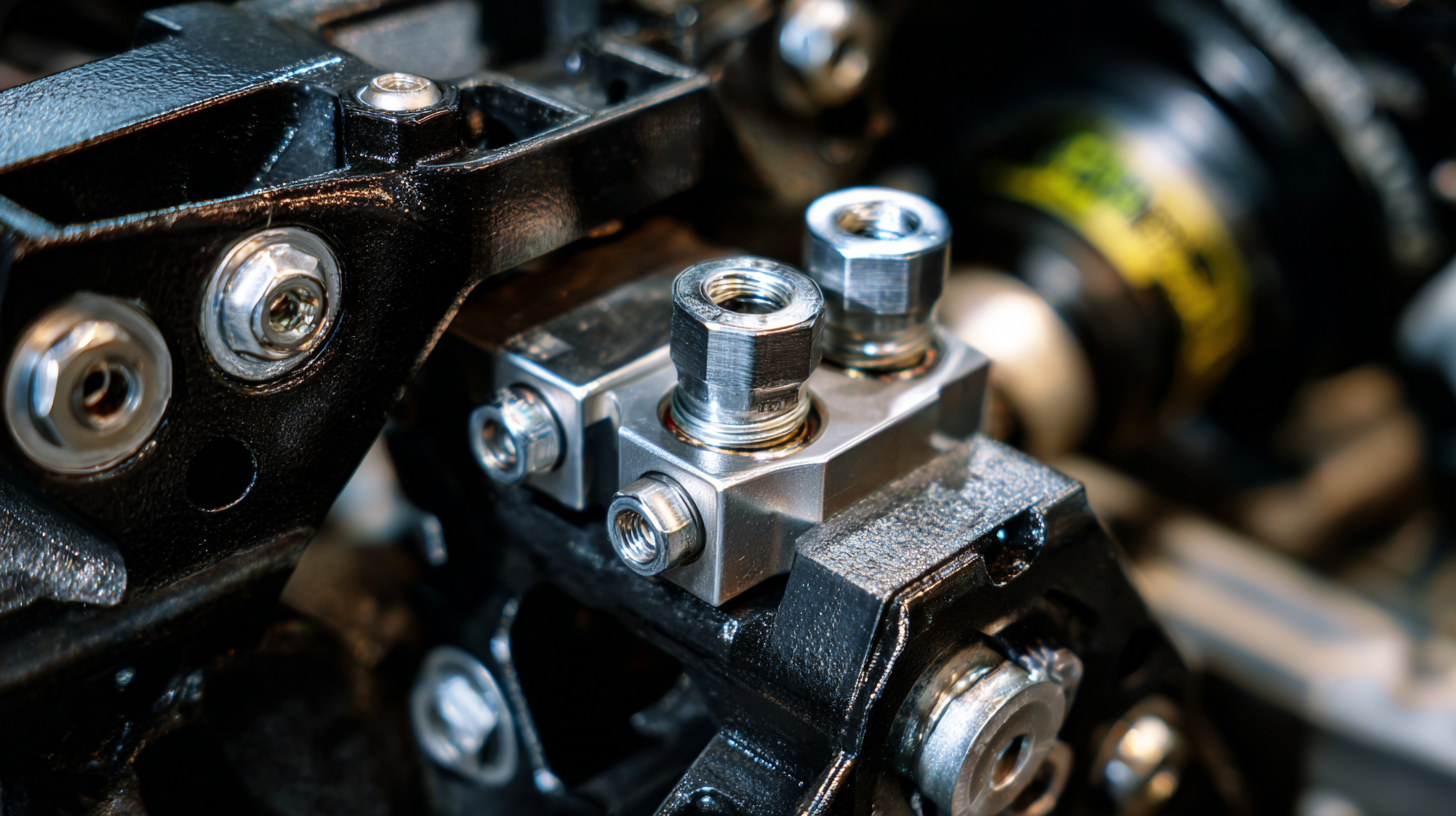

Essential to this process are the "Parts For Machine," which play a critical role in determining overall equipment effectiveness. Each component, from advanced sensors to high-efficiency motors, contributes to increased reliability and performance, thereby impacting the bottom line.

This blog will explore the top examples of the best parts available for machine upgrades, highlighting innovations that can transform operational efficiencies and boost productivity in various industrial applications.

Identifying High-Quality Suppliers for Machine Parts Upgrades

When it comes to upgrading machinery, identifying high-quality suppliers for essential components is paramount. Businesses looking to enhance their operational efficiency must explore options that not only promise durability but also cutting-edge technology. Recent events, such as the Global Digital Economy Conference, emphasize the importance of innovation in industrial upgrades. The emergence of advanced GPUs is a prime example of how tech can propel industrial intelligence, making it vital for organizations to partner with suppliers who are at the forefront of these advancements.

Furthermore, the ongoing transformation within the manufacturing sector underscores the need for a structured supply chain. Reports from industry conferences have showcased successful digital supply chain platforms that aim to improve efficiency by fostering collaboration among suppliers. By prioritizing suppliers that embrace technological progress and streamlined processes, businesses can ensure they have the best parts to facilitate machine upgrades, ultimately leading to enhanced productivity and sustainable growth.

Key Features to Look for When Selecting Machine Upgrade Components

When selecting components for machine upgrades, there are several key features that should be prioritized to ensure optimal performance and longevity. First and foremost, compatibility is crucial. Upgraded parts must fit seamlessly with existing systems, which means checking specifications, dimensions, and connection types.

Additionally, look for components that support future scalability. A forward-thinking approach ensures that any upgrade can accommodate potential expansions or enhancements down the line.

Another essential feature to consider is the reliability of the components. Quality materials and manufacturing processes contribute significantly to the durability and efficiency of machine parts. Look for reputable manufacturers with proven track records in providing robust components. Furthermore, consider the ease of installation and maintenance. Upgrades that facilitate quick setups and require minimal downtime can lead to increased productivity.

A user-friendly design also aids in troubleshooting and repairs, reducing the overall operational impact. By prioritizing these features, you can make informed decisions that will enhance the performance of your machines.

Top Strategies for Effective Supplier Collaboration and Communication

Effective collaboration and communication with suppliers is essential for successful machine upgrades. Establishing strong relationships with your suppliers can lead to higher quality parts and faster turnaround times. One key strategy is to maintain open lines of communication. Regularly scheduled meetings and updates can ensure that both parties are aligned on project goals and timelines. This proactive approach helps to mitigate issues before they arise, fostering a more efficient upgrade process.

Another important tip is to leverage technology for better collaboration. Utilizing project management tools and shared platforms can streamline communication and provide real-time updates. This ensures that all stakeholders have access to crucial information, reducing the likelihood of misunderstandings. Additionally, these tools can facilitate easier tracking of supplier performance and project milestones, enhancing overall accountability.

Finally, investing time in understanding your supplier’s capabilities and processes can greatly improve collaboration. By recognizing their strengths and weaknesses, you can tailor your requests and expectations accordingly. This mutual understanding builds trust and allows for more innovative solutions during upgrades, ultimately resulting in improved machine performance and reliability.

Exploring the Top Examples of Best Parts For Machine Upgrades - Top Strategies for Effective Supplier Collaboration and Communication

| Part Name | Type | Supplier Collaboration Strategy | Communication Method | Upgrade Impact |

|---|---|---|---|---|

| High-Performance Engine | Engine | Joint Development Workshops | Video Conferencing | Improved Efficiency |

| Advanced Control System | Control System | Regular Feedback Loops | Email Updates | Enhanced Precision |

| Energy-Efficient Motor | Motor | Collaborative Design Reviews | Instant Messaging | Cost Reduction |

| Robust Hydraulic System | Hydraulic System | Strategic Partnership Meetings | Face-to-Face Meetings | Increased Reliability |

| Durable Conveyor Belts | Conveyor System | Integrated Supply Chain Approach | Regular Webinars | Reduced Downtime |

Case Studies: Successful Machine Upgrades by Industry Leaders

In the rapidly evolving landscape of machine upgrades, industry leaders are consistently pushing the boundaries of technology to enhance efficiency and productivity. Recent case studies highlight significant advancements, particularly in sectors like manufacturing and logistics. According to a report by the International Federation of Robotics, global sales of industrial robots reached a record high in 2022, exceeding 500,000 units, underscoring the urgent need for businesses to invest in modernized machinery. Companies that have embraced these updates report an average productivity increase of up to 30%.

Additionally, the recent discussions at the Low Altitude Economy and Satellite Internet Security Forum emphasize the importance of integrating cutting-edge technologies. Industry leaders recognize that by leveraging advancements in satellite communications and low-altitude drone operations, they can optimize logistics and supply chain processes. In fact, a study from MarketsandMarkets forecasts that the global market for drone logistics will reach $29.07 billion by 2027, driven by the increasing demand for efficient delivery systems. These examples demonstrate that strategic machine upgrades not only foster operational excellence but also position companies to remain competitive in an increasingly tech-driven market.

The Future of Machine Parts: Trends to Watch for in Supplier Selection

In today's fast-evolving manufacturing landscape, selecting the right suppliers for machine parts is critical to maintaining competitive advantage. Recent reports indicate that nearly 70% of manufacturers are prioritizing innovation in their supply chains, characterizing the need for advanced materials and technologies. As Industry 4.0 continues to gain traction, companies must consider suppliers that not only meet current demands but also align with future technological advancements, such as automation and artificial intelligence integration.

Tip: When assessing potential suppliers, focus on their track record with advanced technologies and their ability to adapt to changing industry needs. The importance of sustainability is also growing, with 50% of manufacturers now indicating they will switch suppliers if sustainability practices are not met.

Additionally, data from a recent industry analysis shows that 65% of businesses are investing in suppliers who offer comprehensive data analytics capabilities. This trend underscores the critical role of data in enhancing decision-making processes and optimizing machine performance. Supplier selection should therefore include a thorough evaluation of their data management systems and their potential to integrate seamlessly with your existing operations.

Tip: Evaluate how suppliers utilize data analytics not just for supply chain efficiency, but also for predictive maintenance and enhancing machine longevity.