Top 10 Machine Welding Machines You Need to Know?

When it comes to welding, a Machine Welding Machine plays a crucial role in modern fabrication. These machines offer precision and efficiency. Yet, finding the right one can be overwhelming. Each machine has unique features to consider.

This article explores the top 10 machine welding machines you need to know. From industrial powerhouses to compact models, there is a machine for every need. However, it's essential to reflect on the limitations of each type. Some machines may lack portability, while others might require extensive training.

Welding requires skill and understanding. A machine cannot replace the human touch. Therefore, even with advanced technology, mistakes can happen. Evaluating your specific requirements is key. Investing in the right machine can elevate your projects, but it comes with challenges. Make informed choices and understand the capabilities of your Machine Welding Machine.

Overview of Machine Welding Technologies

Machine welding technology has evolved significantly in recent years. With the demand for efficiency and precision in manufacturing, technologies like MIG, TIG, and robotic welding are gaining traction. According to a recent industry report, the global machine welding market is expected to reach $10 billion by 2025, highlighting its importance in modern production lines.

MIG welding, known for its speed, accounts for a large portion of machine welding applications. It simplifies the process and reduces labor costs. However, the quality can vary, often requiring skilled operators for optimal results.

TIG welding provides excellent control over the welding process, ideal for thin materials. Despite its advantages, it demands more time and training.

Robotic welding, another emerging technology, brings automation to the forefront. It increases production rates while minimizing human error. However, the initial investment can be substantial. Companies must weigh the benefits against costs.

As with any technology, ongoing maintenance is crucial. Neglecting this can lead to decreased efficiency and increased downtime. Understanding these technologies is essential for manufacturers looking to stay competitive.

Criteria for Selecting a Welding Machine

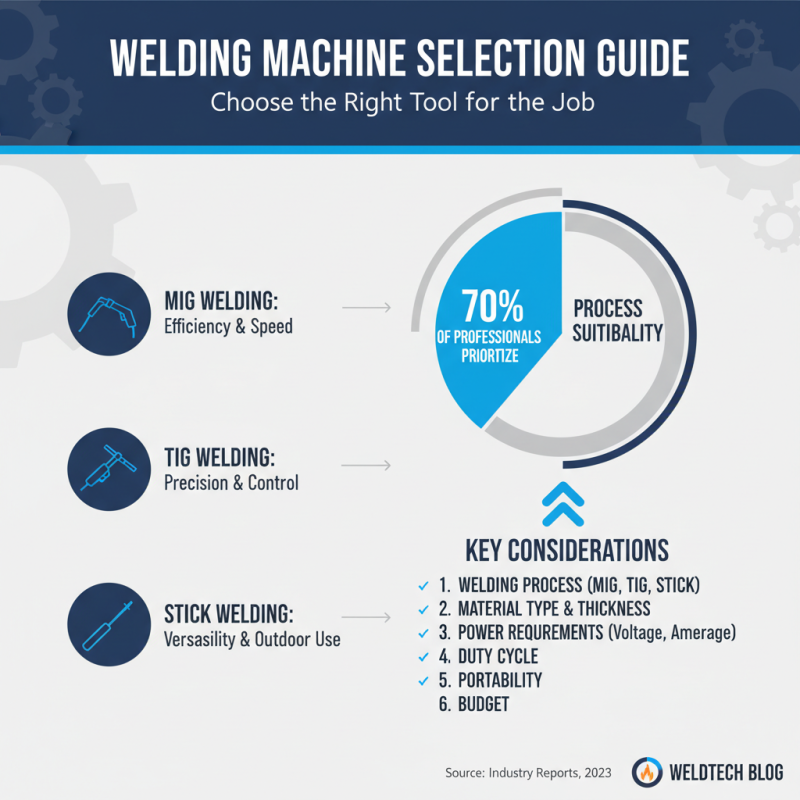

When selecting a welding machine, several criteria must be considered. First, the type of welding process is crucial. Different machines cater to MIG, TIG, or stick welding. Each method has distinct advantages. For instance, MIG welding is often preferred for efficiency while TIG offers superior precision. According to industry reports, 70% of welding professionals prioritize process suitability over other features, emphasizing its importance.

Power output is another key factor. Machines must provide enough amperage for the materials being welded. Insufficient power can lead to weak welds and project failures. Data shows that 65% of welders experience issues due to inadequate power settings. It’s vital to assess the project's demands before making a purchase.

Portability and ease of use are essential, especially for fieldwork. Heavy machines can limit accessibility. The welding machine should balance weight and functionality. Many users report frustration with complicated setups that waste time. A simple, efficient machine can significantly enhance productivity. Ultimately, understanding personal needs and project requirements can lead to better investment decisions.

Top 10 Machine Welding Machines and Their Features

When considering machine welding machines, it's essential to explore their features in depth. Many options available today offer a mix of efficiency and versatility. Certain models focus on portability, making them ideal for job sites. Others are designed for heavy-duty operations, suitable for more extensive projects.

One important feature to think about is the type of welding process the machine supports. Options like MIG, TIG, and stick welding provide different capabilities. For example, MIG welding machines often promise speed, making them popular in various industries. Meanwhile, TIG machines are known for precision, which some users find challenging. Beginners might struggle with settings, leading to frustration and inconsistent results.

Another detail to note is power requirements. Some machines demand a stable power supply, while others are adaptable to various settings. This can be a significant factor for users with limited resources. Not every machine excels in every task. Users often need to reflect on their specific needs. Understanding these features can prevent common pitfalls in the selection process.

Applications of Machine Welding Machines

Machine welding machines play a crucial role across various industries. In construction, for instance, these machines streamline the joining of metal components. They improve efficiency and maintain structural integrity. Reports indicate that the global welding machine market is expected to grow by 5% annually, reflecting rising demand.

In automotive manufacturing, machine welding is essential. It ensures precision in assembling parts like chassis and frames. Automation reduces human error, enhancing safety and quality. Approximately 70% of automotive manufacturers utilize automated welding, showcasing the trend toward advanced technology in production. However, not all companies adapt swiftly. Some still rely on outdated methods, risking competitiveness.

Moreover, in the aerospace sector, machine welding is vital for lightweight components. This sector demands high-quality welds to withstand extreme conditions. Data shows that 80% of aerospace designs incorporate welded joints, highlighting their significance. The challenge remains for companies to balance innovation with investment. Many are hesitant to abandon traditional methods despite the clear advantages machine welding offers. This reflects a need for industry-wide reflection.

Top 10 Machine Welding Machines You Need to Know

| Machine Name | Type | Welding Process | Power Source | Applications |

|---|---|---|---|---|

| Welding Robot A | Automated | MIG | Electric | Automotive, Aerospace |

| Welding Machine B | Portable | TIG | Gas | Maintenance, Repair |

| Multi-Process Welder C | Industrial | MIG/TIG/Stick | Electric | Fabrication, Construction |

| Submerged Arc Welder D | Stationary | SAW | Electric | Heavy Industries, Shipbuilding |

| Plasma Cutter E | Portable | Plasma | Electric | Metal Cutting, Fabrication |

| Welding Machine F | Automatic | MIG | Gas | Manufacturing, Assembly Lines |

| Electrode Welder G | Manual | Stick | Electric | Construction, Repair |

| Spot Welder H | Stationary | Spot | Electric | Thin Sheet Metal, Electronics |

| Laser Welder I | Industrial | Laser | Electric | Medical, Aerospace |

| Flux-Cored Welder J | Portable | FCAW | Electric | Heavy Equipment, Pipeline |

Future Trends in Machine Welding Technology

The future of machine welding technology is rapidly evolving. Innovative techniques and tools are enhancing productivity and precision. Automation is playing a crucial role. As machines become smarter, they adapt to complex tasks. This trend can lead to increased efficiency and reduced costs.

Tips: Always invest in training. Skilled operators can maximize the potential of new machines. Understand the software that controls these technologies. Regular updates can enhance performance.

Collaboration between humans and machines is vital. Robotic welders are now working side by side with operators. However, reliance on automation raises concerns. There can be a lack of human oversight. If issues arise, quick resolutions are needed.

Tips: Maintain a balance between automation and human skill. Regular assessments can prevent oversights. Understand the limitations of technology. Always have a backup plan in place.

Related Posts

-

Elevate Your Operations with the Best Welding Machines Made in China for Global Markets

-

Transforming Industries with Best Plastic Material Machine Practical Applications and How to Implement Them

-

Exploring the Top Examples of Best Parts For Machine Upgrades

-

Unlocking the Best Production Machine Technical Specifications and How to Maximize Efficiency

-

Revolutionizing the Industry: How Packing Machines Enhance Efficiency and Sustainability

-

5 Reasons Why Best Parts Machine is the Ultimate Choice for Global Buyers