Top Strategies for Sourcing the Best Welding Machines in the Global Market

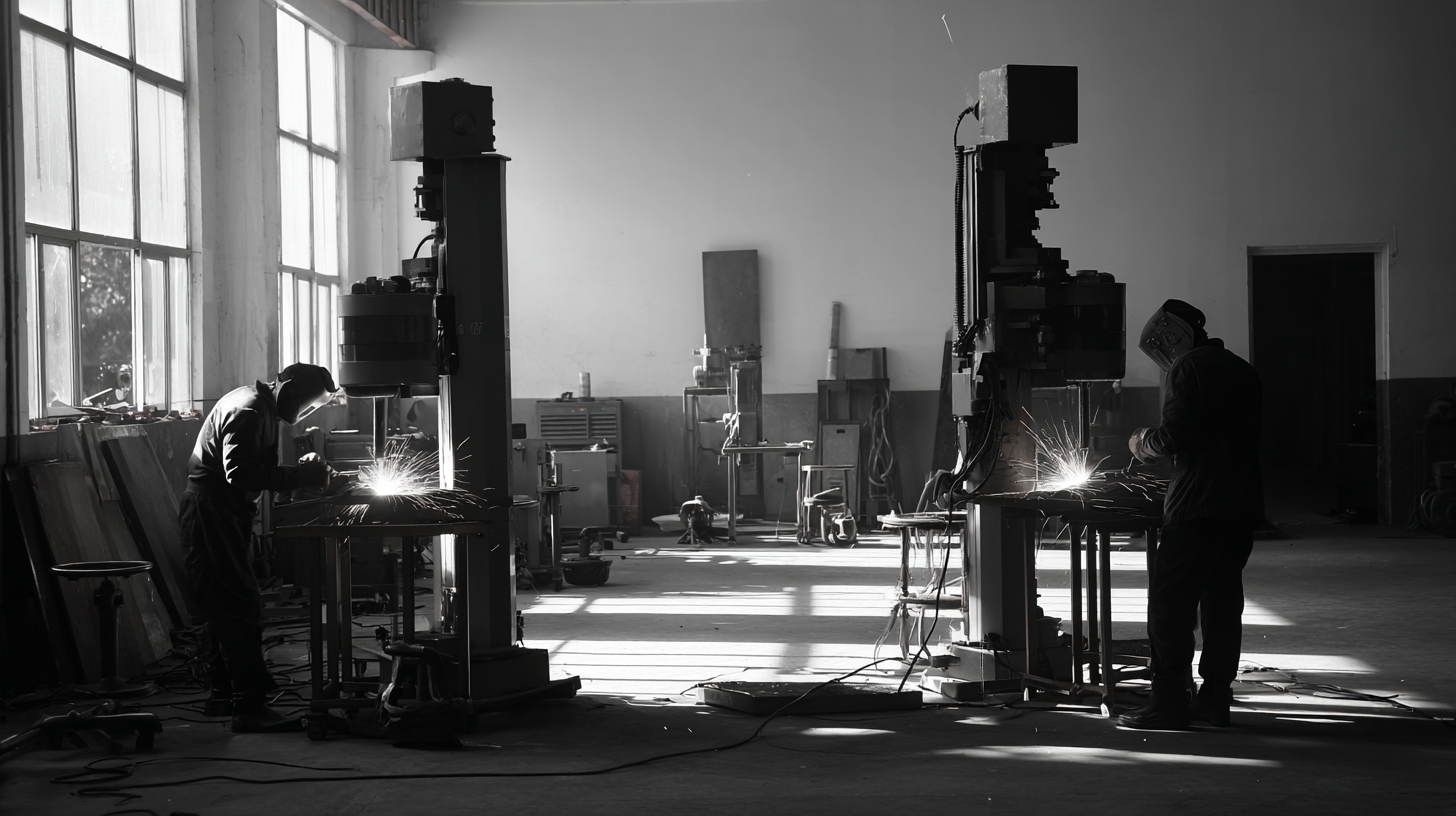

In the rapidly evolving landscape of manufacturing, the demand for high-quality welding machines has surged, driven by the expansion of industries ranging from automotive to construction. According to a recent market report by ResearchAndMarkets, the global welding equipment market is projected to reach approximately $21.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.8% from 2020. As manufacturers and suppliers compete on the international stage, it is essential to adopt effective sourcing strategies to identify the best welding machines that not only meet production needs but also align with global standards of quality and efficiency. With China’s robust manufacturing capabilities, known for producing reliable and innovative welding machines, exporters are increasingly looking towards the Middle Kingdom for solutions that enhance competitiveness in the global market. This blog will explore key strategies for sourcing the best welding machines, ensuring that businesses can thrive in an increasingly interconnected and dynamic industry.

Identifying Emerging Trends in Welding Technology for 2025

As we look ahead to 2025, emerging trends in welding technology are poised to significantly shape the landscape of the industry. Key developments such as automation and advanced materials are not just buzzwords; they represent a shift in how welding processes are approached. The integration of automated welding systems facilitates increased precision and efficiency, which translates to reduced operational costs and improved safety in manufacturing environments.

Additionally, the emphasis on sustainability cannot be overstated. Companies are increasingly exploring eco-friendly welding solutions that minimize waste and energy consumption. The demand for laser welding systems is a prime example of this trend, as these systems offer high efficiency and precision while reducing environmental impact. As we navigate the evolution of welding technology, it is crucial for industry players to stay informed about these trends to remain competitive and innovate effectively in the global marketplace.

Evaluating Key Features and Specifications of Welding Machines

When sourcing the best welding machines in the global market, evaluating key features and specifications is crucial. According to a report by Grand View Research, the global welding equipment market is expected to reach USD 27.75 billion by 2027, driven by advancements in technology and increasing demand for construction and manufacturing. To make an informed purchase, one must assess essential specifications such as duty cycle, welding process types (MIG, TIG, Stick), and power output. A machine with a higher duty cycle offers prolonged usage without overheating, making it essential for demanding industrial applications.

Additionally, 2023 industry insights show that portability and ease of use have emerged as critical factors for both hobbyists and professionals. Welding machines weighing under 50 pounds and those featuring inverter technology are becoming popular, as they provide compactness without sacrificing performance. The choice of power source—whether electric, gas, or diesel—also plays a significant role, with electric welding machines dominating due to their efficiency and environmental benefits. As the industry evolves, staying informed about these specifications will ensure that sourcing the right welding machine meets both current and future needs.

Top Strategies for Sourcing the Best Welding Machines in the Global Market

Assessing Global Suppliers: Where to Find Reliable Welding Equipment

When it comes to sourcing the best welding machines on the global market, understanding where to find reliable suppliers is crucial. The demand for high-quality welding equipment is on the rise, driven by various industries adapting to advanced manufacturing processes. Recently, the market for engine-driven welders is projected to grow substantially, highlighting the increasing need for efficient and portable welding solutions. This provides an excellent opportunity for businesses and manufacturers to explore and engage with reputable suppliers who specialize in these high-demand products.

In assessing global suppliers, it's essential to evaluate their product offerings and market presence. For instance, the demand for portable weld path cleaners and their growing acceptance in the industrial sector further signifies the shift towards more versatile welding machines. Suppliers that offer comprehensive options—including both manual and automatic spot welding machines—can cater to a variety of customer preferences. By focusing on suppliers with a solid track record and innovative product lines, businesses can ensure they source reliable welding equipment that meets market needs and enhances operational efficiency.

Comparative Analysis of Price and Performance: Making Informed Choices

When sourcing the best welding machines in the global market, it's crucial to conduct a comparative analysis of price and performance. Understanding the spectrum of available machines involves more than just comparing costs; it also requires evaluating how well different models meet your specific welding needs. Brands may offer varying capabilities, such as ease of use, power efficiency, and quality of welds, which all factor into their overall value. By analyzing these attributes along with pricing, you can make informed decisions that align with your budget and project requirements.

Moreover, considering the total cost of ownership is essential. This includes not just the initial purchase price but also factors such as maintenance costs, spare parts availability, and warranty offerings. A machine that appears more expensive upfront may prove to be more economical in the long run if it offers superior durability and performance. Additionally, user reviews and expert recommendations can provide invaluable insights into the real-world performance of welding machines, helping you to identify models that deliver the best results for your investment.

Top Strategies for Sourcing the Best Welding Machines in the Global Market - Comparative Analysis of Price and Performance: Making Informed Choices

| Machine Type | Price ($) | Power (W) | Weight (kg) | Performance Rating (1-10) | User Satisfaction (%) |

|---|---|---|---|---|---|

| MIG Welder | 1200 | 200 | 25 | 8 | 92 |

| TIG Welder | 1500 | 300 | 20 | 9 | 90 |

| Stick Welder | 800 | 150 | 30 | 7 | 85 |

| Multi-Process Welder | 1800 | 350 | 27 | 9 | 88 |

| Plasma Cutter | 2000 | 400 | 15 | 10 | 95 |

Navigating Compliance Standards in the Welding Equipment Market

Navigating compliance standards in the welding equipment market is crucial for sourcing high-quality welding machines globally. The International Organization for Standardization (ISO) has outlined rigorous standards that welding equipment must meet to ensure safety and efficiency. According to a recent report from the American Welding Society (AWS), approximately 25% of welding equipment manufacturers face challenges when aligning their products with these standards, which can lead to costly penalties and safety hazards. Understanding these compliance requirements not only enhances product reliability but also boosts a company's reputation in a competitive marketplace.

Furthermore, the European Union's machinery directives necessitate that welding equipment meets specific technical and health standards before being sold in the EU market. As reported by the European Welding Federation, failure to comply can result in up to €200,000 in fines and recalls. This highlights the importance of due diligence in the sourcing process. Buyers should prioritize equipment that carries appropriate certifications, such as CE marking, which indicates the product meets relevant EU regulations. By focusing on compliance, companies can avoid regulatory setbacks and ensure operational efficiency, while also fostering sustainability in their sourcing strategies.