Understanding the Best Production Machine: Technical Specifications and Usage Guide for Global Buyers

In an era marked by rapid technological advancements, the demand for effective and efficient production machines has never been higher. According to a recent report by Market Research Future, the global production machines market is projected to reach USD 1,080 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.5%. This surge is driven by the increasing need for automation and precision in manufacturing processes across various industries. As global buyers navigate the complex landscape of production machinery, understanding the essential technical specifications and their practical applications becomes crucial. This guide aims to illuminate the key features and optimal usage of production machines, enabling manufacturers to make informed decisions while aligning with industry trends and future growth projections.

Key Features of China's Leading Production Machines for Global Markets

In recent years, China's production machines have gained significant traction in global markets, largely due to their advanced technology and cost-effectiveness. According to a report by ResearchAndMarkets, the global manufacturing equipment market is projected to reach $1,200 billion by 2026, with Chinese manufacturers capturing a substantial share thanks to innovations in automation and precision engineering. Key features of these machines include high-speed operations, adaptability to various materials, and integration with Industry 4.0 technologies, which enhance productivity and reduce operational costs.

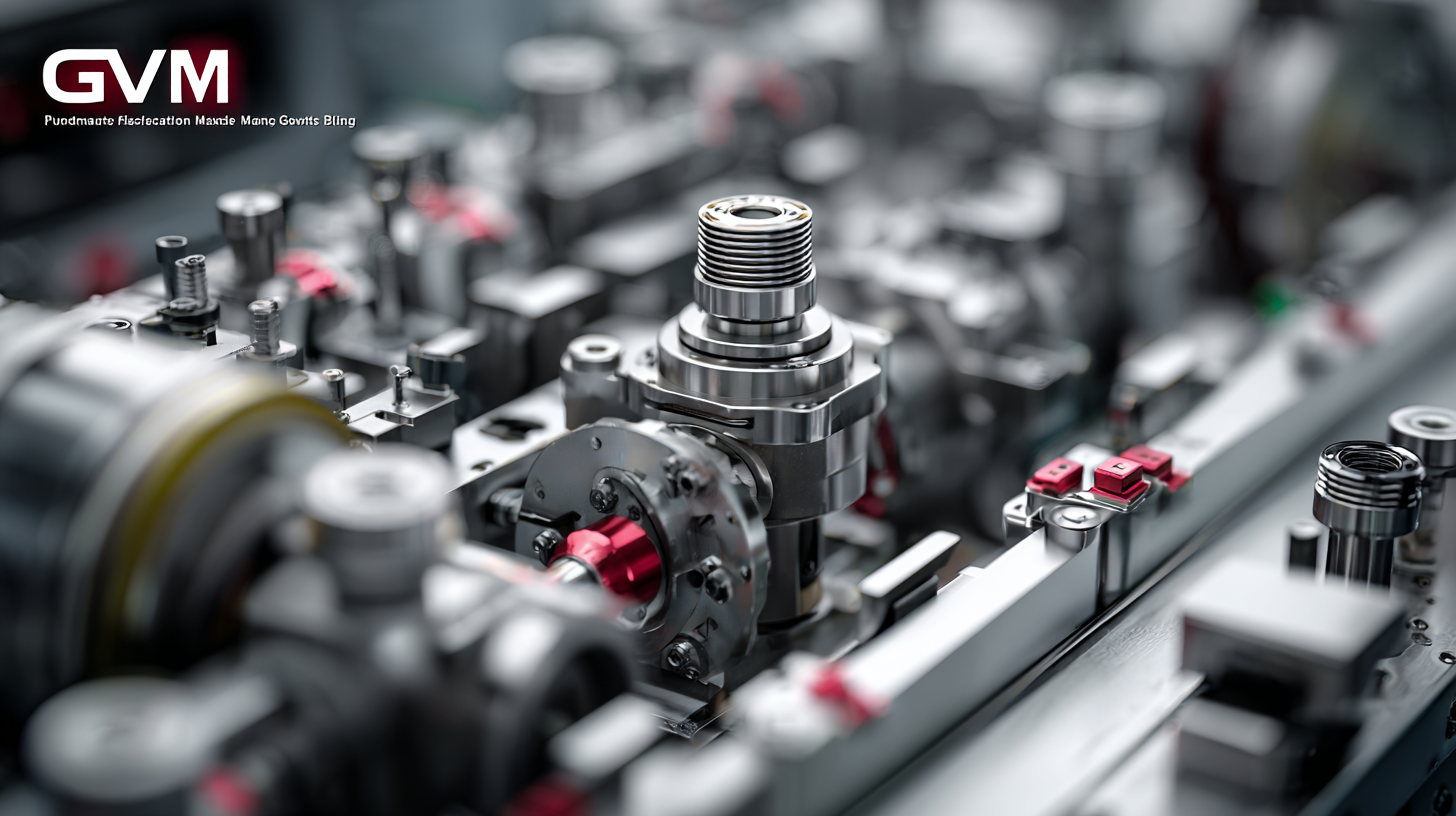

One standout category is CNC machining centers, which have seen a 12% growth in international sales from 2020 to 2023. These machines are equipped with state-of-the-art software for complex processes, significantly improving efficiency while minimizing human error. Furthermore, China's leading production machines often come with enhanced energy efficiency ratings, addressing the growing demand for sustainable manufacturing practices. As global buyers seek reliable and efficient solutions, understanding the intricacies of these machines can provide a competitive edge in the rapidly evolving market landscape.

Understanding the Technical Specifications: What Buyers Need to Know

When considering the purchase of a production machine, understanding the technical specifications is crucial for making informed decisions. Buyers must focus on key parameters such as power output, operational efficiency, and automation capabilities. For instance, a recent report by MarketResearchFuture indicates that machines with a power output exceeding 200 HP tend to achieve a 20% increase in productivity compared to their lower-output counterparts. Additionally, efficiency ratings such as Overall Equipment Effectiveness (OEE) can be a game-changer, as machines with an OEE above 85% are significantly sought after for their reliability and efficiency.

Tip: Before making a purchase, always request a demo or a trial period. This allows you to validate the machine's performance under your specific operational conditions, ensuring it meets your production needs.

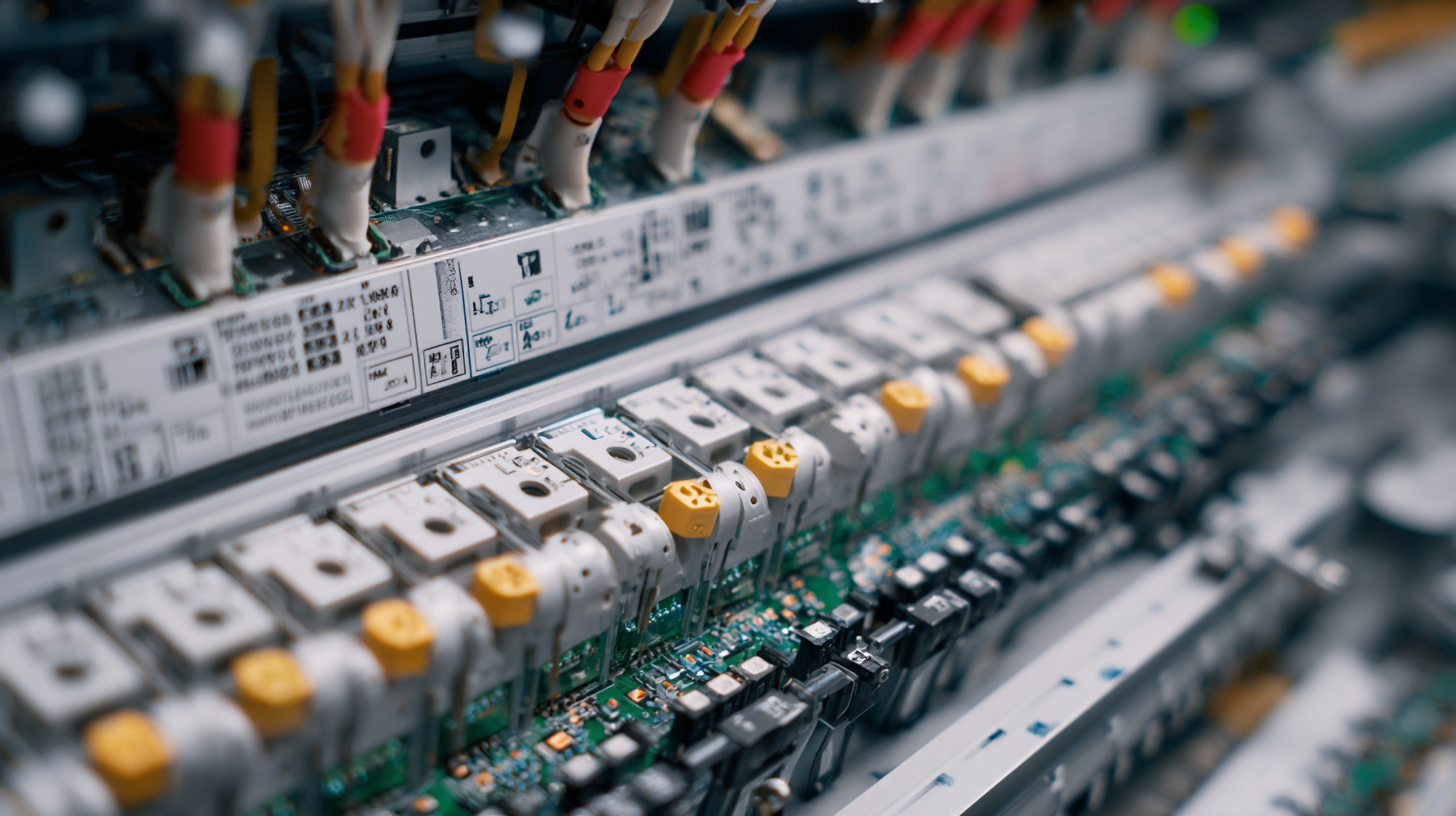

Another critical specification to consider is the machine's compatibility with Industry 4.0 technologies. As factories worldwide evolve towards smart manufacturing, the ability for machines to integrate with IoT and big data analytics is becoming essential. A study by Deloitte highlighted that companies utilizing connected machines are achieving a 30% reduction in downtime, leading to substantial cost savings.

Tip: Look for machines that offer flexible software updates and compatibility with existing systems. This adaptability can future-proof your investment as technology rapidly advances in the manufacturing sector.

Comparative Analysis: Chinese Manufacturing vs. Global Competitors

The competitive landscape of manufacturing is continuously evolving, with China's manufacturing sector often highlighted as a dominant force. According to a report by McKinsey & Company, China's manufacturing output accounted for over 28% of the global total in 2021, significantly outpacing the United States, which held approximately 16%. One of the key advantages of Chinese manufacturing is its impressive scale and efficiency, underpinned by large investments in automation and technology. This has allowed manufacturers to achieve lower production costs, making them attractive options for global buyers seeking cost-effective solutions.

However, it's essential to recognize that while China's manufacturing prowess is formidable, it is facing mounting competition from other regions. For instance, countries like Vietnam and India are emerging as viable alternatives due to their lower labor costs and increasing investment in technology. A report from the Boston Consulting Group noted that Vietnam's manufacturing sector is projected to grow at a 6-8% annual rate, fueled by foreign investments and government support. Additionally, initiatives in India, such as the "Make in India" campaign, aim to enhance the local manufacturing ecosystem, presenting global buyers with new opportunities outside of traditional hubs. As the market diversifies, understanding these dynamics becomes critical for buyers looking for the best production machines tailored to their specific needs.

Usage Guidelines: Maximizing Efficiency in Production Machine Operation

In the world of manufacturing, maximizing efficiency is crucial for maintaining a competitive edge. Understanding the operational guidelines of production machines can significantly enhance their performance and lifespan. Firstly, it is essential to conduct routine maintenance checks to ensure that all systems are functioning optimally. Regular lubrication of moving parts, calibration of machines, and replacing worn components can prevent unexpected breakdowns that can disrupt production schedules.

In addition to maintenance, training operators on best practices is vital. Workers should be familiar with the specific features and capabilities of the machines they operate. This includes understanding operational limits to avoid overloading the machinery, which can lead to wear and malfunction. Furthermore, implementing a system for monitoring machine performance can generate valuable data that informs adjustments and optimizations in real-time, ensuring that production goals are not just met but exceeded. By prioritizing these guidelines, companies can foster a culture of efficiency and reliability in their production environments.

Understanding the Best Production Machine: Technical Specifications and Usage Guide for Global Buyers

| Dimension | Specification | Usage Guidelines | Efficiency Tips |

|---|---|---|---|

| Power Source | Electric, 220V | Ensure stable power supply | Use UPS for power fluctuations |

| Production Capacity | 1000 units/day | Optimize production schedules | Analyze peak production times |

| Operating Temperature | 15°C - 30°C | Maintain ambient conditions | Utilize HVAC systems |

| Dimensions | 2m x 1.5m x 1.8m | Ensure sufficient floor space | Plan layout in advance |

| Weight | 500 kg | Check load capacity of floors | Use appropriate lifting equipment |

Trends in Exporting Chinese Manufacturing Equipment Worldwide

In recent years, the global demand for manufacturing equipment has surged, and Chinese manufacturers have been at the forefront of this trend. With advancements in technology and production efficiency, China has positioned itself as a leading exporter of manufacturing machinery. Many international buyers are now keen on understanding the technical specifications of these machines to ensure they are making informed purchasing decisions.

When considering the purchase of manufacturing equipment, buyers should pay attention to key specifications such as production capacity, energy efficiency, and maintenance requirements. It’s essential to evaluate the compatibility of the machinery with existing production lines and processes.

**Tips:** Always request detailed specifications and performance data from the supplier, as this will help in assessing the true value of the equipment. Additionally, consider visiting manufacturing facilities to witness the machinery in action and understand its operational intricacies. Engaging with other businesses that have experience using the same equipment can also provide valuable insights into long-term performance and reliability.